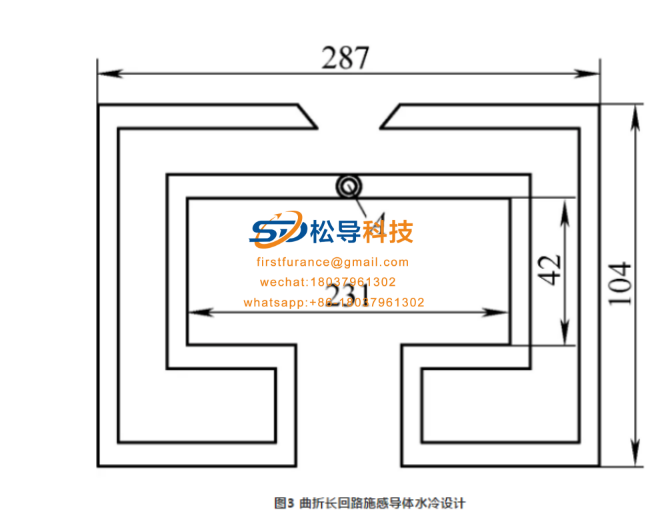

For the self-spraying continuous heating quenching inductor, the amount of cooling water and its circuit layout should be fully considered. Induction hardening is generally used pressure 0.3 ~ 0.4MPa , when the electrical sensing conductor circuit is longer, and the more tortuous water hole shape, it is easy to produce " hold water " or " without water " phenomenon, burn or cause the sensor workpiece quenching A soft band appears. FIG. 3 shows a slider for induction hardening of electrical sensing conductor inductor coil length, winding circuit, when the water continuous double Hardening, easily at A at the " hold water " burned electric somatosensory, The solution is to add a water outlet at this location.

Calculated cooling capacity, when the pressure is 0.3 ~ 0.4MPa , the flow sectional area of 32 ~ 80mm2 seal may be used to power the watercourse 30 ~ 150kW of electrical sensing conductor cooling. For small area (quenching bandwidth of ≤ 40mm ) frequency quenching electrical sensing conductor (continuous), the induced eddy currents due to poor efficiency, electric somatosensory heat easily, coupled with a small number of spray holes, so that the effective small flow of cooling water, will eventually cause the electrical Poor cooling of the sensory body. At this time, if more common double water quenching cooling mode, it will make electrical vivo sensing cooling water flow rate is much smaller than the electrical somatosensory limit the flow of cooling requirements of easy electrical blown somatosensory busbar junction, so that the explosion occurs Water leaks. In this regard, the cooling water should be used in a specific manner into a cooling electrical sensing conductor, and another design for a separate quench water spray quench ring.

Machine tool guide rail quenching equipment : http://www.songdaokeji.com/plus/view.php?aid=208