General specifications selected according to the process, the gap-designed electrical sensing conductor, induction hardening can achieve the required work. When the equipment is selected, the output power is also basically determined. At this time, the surface specific power obtained by actually heating the surface mainly depends on the heating area and heating efficiency. If the heating area is too large, the specific power decreases and the heating area cannot be quenched. The temperature may produce quenched soft belt.

Referring to the induction heating equipment design parameters and specifications, proven production plant, in the design process, according to the parameters shown in schedule for electrical sensing conductor design and process design.

Specific power and maximum heating area

frequency | Equipment power / kW | Specific power / kW · cm -2 | Maximum heating area / cm2 | ||

Simultaneously Quenching method | continuous Quenching method | Simultaneously Quenching method | continuous Quenching method | ||

High frequency ( 200 ~300kHz ) | ( GP100 ) 100 | 1.1 | 2.2 | 90 | 45 |

Intermediate frequency ( 8kHz ) | (Generator) 100 | 0.8 | 1.25 | 125 | 80 |

(Generator) 160 | 0.8 | 2 | 250 | 100 | |

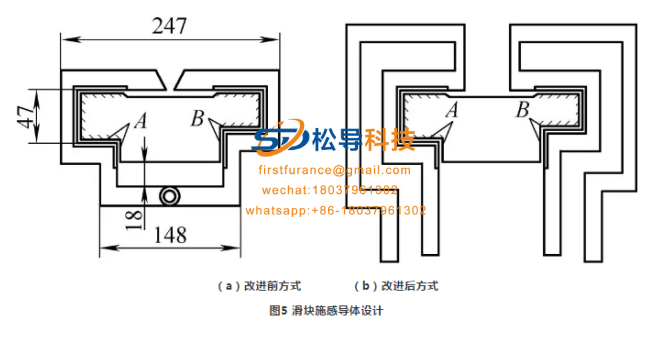

Is to slide the electrical design sense conductor power calculation will be described, and the first slider design electrical sensing conductor in FIG. 5a , the use of GP100 apparatus for continuously quenching, 10mm ×. 8 mm rectangular pipe, a gap 3mm , from the test power somatosensory 8mm surface of the workpiece is also heated oxidized, i.e., the presence of magnetic field lines to escape, has been unable to control the quenching zone while Yin portion reaches a predetermined temperature, the hardness serious unevenness, a , B and basically no quenching hardness.

Analysis: 1 Power check. According to the actual heating situation, the continuous heating surface area S actual = 44.5cm2 . Checking the attached table shows that the maximum allowable heating area has been reached, and the transmission loss of the sensor makes the power insufficient. 2 The heating efficiency varies greatly, the heating efficiency of the A and B sides is the worst, and the heat dissipation conditions are the best, it is difficult to reach the heating temperature.

Improvement of the problems of the electrical sensing conductor, as shown in 5b shown in FIG. Contoured body that is divided into two, the maximum effective core area, FIG. 5a in S Left = 15.7cm2 , FIG. 5b the S Right = 15.2cm2 , are in line with schedule requirements, to ensure sufficient heating power, reducing the amount of quench surface easy to operate, while Reduce the gap between the A and B surfaces, thereby improving the heat treatment and meeting the design requirements

Machine tool guide rail quenching equipment : http://www.songdaokeji.com/plus/view.php?aid=208