Machine tool guide rail quenching equipment has unique process characteristics, short heating time, fast speed, refine quenching structure, and has the effect of strengthening mechanical properties. Induction heat treatment can locally heat parts and implement surface or local strengthening treatment. Therefore, in the production of machine tool parts, a large number of induction heating quenching techniques are used. However, since the surface shape of the parts is very different, in order to make the heating uniform, the structure of the sensor should be continuously improved and updated, and the gap between the induction conductor of the effective circle and the parts should be kept at a suitable size, so as to obtain the best quenching effect.

The structure, design and selection of the sensor are discussed in detail below.

Structure of machine tool guide quenching equipment sensor

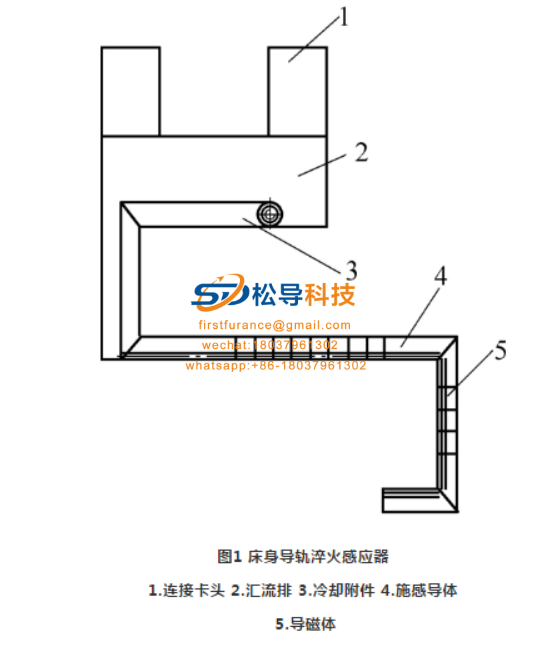

The structure of the sensor is generally composed of the following five parts, as shown in Figure 1 .

( 1 ) The connection chuck's function is to fix the sensor connection at the output port of the induction power supply (secondary of the quenching transformer) and conduct the current to the busbar.

( 1 ) The connection chuck's function is to fix the sensor connection at the output port of the induction power supply (secondary of the quenching transformer) and conduct the current to the busbar.

( 2 ) The bus bar leads the working current to the induction coil, and plays the role of increasing the overall structural strength of the inductor and extending the working area.

( 3 ) The induction conductor (coil) generates electromagnetic eddy current coupling with the surface of the workpiece to be quenched by a certain frequency of induction current, so that the surface is quickly heated to the temperature required for quenching.

( 4 ) Cooling accessories In most continuous quenching induction heating processes, the cooling accessories are used to cool the connection chuck, bus bar and induction coil, and can directly provide a cooling medium for quenching, which greatly simplifies the structure of the inductor.

( 5 ) The magnetizer is based on the practice of actual induction heating. The magnetizer plays an important role in driving and concentrating the magnet during induction quenching. Therefore, the magnetizer should also be analyzed as part of the inductor.

Machine tool guide rail quenching equipment : http://www.songdaokeji.com/plus/view.php?aid=208