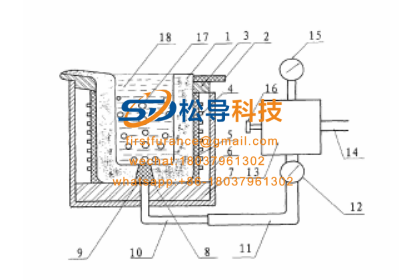

Bottom-blowing induction melting furnace , which is composed of furnace lining, breathable brick, cover plate, upper frame brick, induction ring, insulating fiber and outer shell; it is connected by gas source connected in series, gas regulator, flow meter and gas transmission Hose, metal bellows, gas connection, pressure gauge and regulating valve constitute the gas supply system. The gas supply system is connected to the gas pipe joint through the metal bellows to supply gas to the furnace body. The present invention also discloses a bottom-blown type induction melting furnace assist the refining process, the method used for special steel, alloy steel, metal smelting the induction furnace after all melted embodiment, specifically as follows: First air is introduced through the takeover Inert gas; adjust the regulating valve according to the working conditions, and the pressure of the inert gas delivered to the breathable brick is 0.1 ~ 1 . OMPa , a flow rate of 100 ~ 700 1 / s; furnace secondary refining time . 3 - 5min . It is suitable for intermediate frequency smelting applications with a capacity of less than 250kg . The furnace has a simple structure, good permeability, uniform bubble formation, and the operability and effect of the auxiliary refining process in the furnace.