Induction smelting furnace for special steel, alloy steel and metal refining . When smelting alloy steel and steel with special requirements, the induction melting furnace can be changed from " chemical steel " to steel making, so that its quality index reaches the current AOD , VOD, LF refining furnace, VD vacuum degassing furnace quality level, is an important way for medium and small furnace type smelting and casting enterprises to improve quality and reduce waste products, is a kind of investment, quick effect, low cost, high quality The production process is an environmentally friendly production process with energy saving and consumption reduction, and is a production process with a ton flow.

The bottom of the refining induction melting furnace is equipped with a bottom-blowing refining induction melting furnace with a breathable structure . The refining induction melting furnace has a simple structure, good air permeability and uniform bubble formation. In order to achieve the above technical objectives, the refining induction melting furnace adopts the following technical solutions.

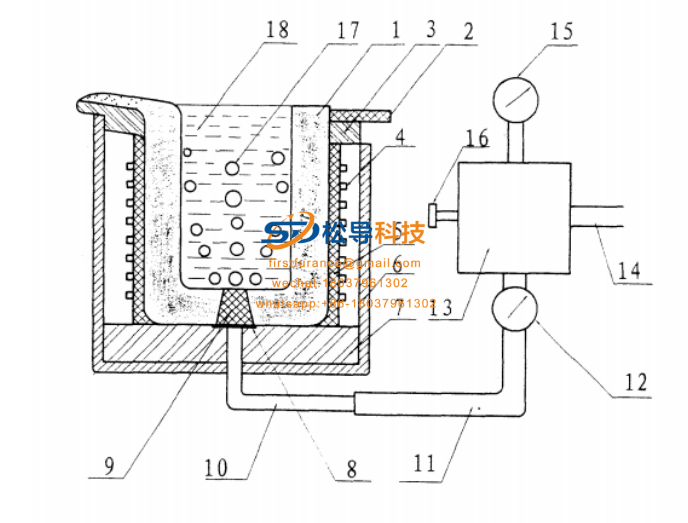

The bottom-blown refining induction melting furnace consists of a furnace body and a gas supply system; the furnace body includes a lining, and a cover plate, an upper frame brick, an induction ring, an insulating fiber, an outer shell, and a furnace substrate plane support On the plane of the base, the furnace lining contains molten steel and bubbles. The gas supply system includes a gas source connection pipe, a gas regulator, a flow meter, a gas transmission hose, a metal bellows, and a gas transmission joint connected in series; the gas regulator is provided with a pressure gauge and a regulating valve. The improvement wherein: said furnace oct-inch ' central bottom of a through hole, the hole plug purging means, interposed between the end faces of the joint lining pipelines and the base bottom and support inclusive purging, gas The joint is connected to the gas supply system through a metal bellows.

The core of the above technical solution is that a gas-permeable brick penetrating the furnace substrate is inserted in the middle of the furnace substrate.

The air-permeable brick has a truncated cone shape. When installed, the small-diameter end faces upward and the large-diameter end faces downward. The end face of the gas pipe joint is between the air-permeable brick and the base. Real cooperation. Breathable bricks are made of high-temperature refractory materials, with a thickness of 60-150mm , and small end faces of breathable bricks with a diameter of 50-180mm .

Compared with the existing technology, the refining induction melting furnace has the following positive effects:

1. The middle of the furnace substrate is filled with breathable bricks and introduced into the gas supply system through the gas pipe joint, the structure is simple, and the manufacture is easy;

2. The inert gas oozes out from the air-permeable bricks, is evenly dispersed, and has good foam formation, which creates conditions for the refining of molten steel in the furnace;

3. The gas supply system is equipped with adjustable gas pressure and flow structure to avoid excessive boiling and splashing of molten steel.

BRIEF DESCRIPTION

The figure is a schematic diagram of the structure of a refining induction melting furnace .

The refining induction melting furnace will be described in detail below with reference to the drawings and embodiments .

The bottom-blown refining induction melting furnace shown in the drawings includes two parts: furnace body and gas supply system. The furnace lining containing 1 , lining and 1 cover the outer periphery of the package 2 , the upper frame brick 3 , the induction coil 4 , an insulating fiber 5 , the housing 6 , lining a planar support bottom in the base 7 on the plane. Both the bottom of the lining 1 and the middle of the base 7 are through holes . The through holes on the bottom of the lining 1 are filled with air-permeable bricks 9 , and the gas pipe joint 8 is sealedly connected to the metal bellows 10 to introduce the gas supply system to the furnace body. The gas supply system from the gas source is connected in turn to take over the string 14 , gas regulator 13 , flow meter 12 , air hose 11 , the metal bellows 12 and the gas pipeline connector 8 composed. The gas regulator 13 is provided with a pressure gauge 15 and a regulator valve 16 . This embodiment is applied to a bottom-blown refining induction melting furnace with a capacity of 250 kg . The bottom of the lining 1 is equipped with a breathable brick 9 and the small end face has a diameter of 180 mm and a thickness of 150 mm , which can meet the refining requirements in the furnace. The refining induction melting furnace is filled with a gas-permeable brick in the middle of the furnace substrate and is introduced into the gas supply system through the gas pipe connection.

The structure is simple and the production is easy. The inert gas oozes out from the air-permeable bricks, is evenly dispersed, and has good foam formation, which creates conditions for steel liquid refining. Refining induction melting furnace is particularly suitable for the capacity of less than 250kg induction melting furnace applications.