The new coreless induction melting furnace shell has high strength and good rigidity, which can effectively prevent the stress and deformation of the furnace lining and strengthen the electric furnace structure; and the overall installation is simple, and it is easy to repair the induction coil and yoke inside the shell. The utility model is characterized in that the furnace shell is a group of H- shaped steels whose lower ends are fixed on the periphery of the furnace bottom steel frame and are perpendicular to the furnace bottom steel frame , and a gap is left between two adjacent H- shaped steels, and the interval is kept the same. The bottom steel frame of the furnace can be the same as the bottom steel frame of the existing cylindrical coreless induction melting furnace , or other shapes. The upper end of the H- shaped steel can be fixed on the periphery of the same furnace stiffener ring to maintain the overall stability. Of course, the shape of the rim of the furnace stiffener ring should be the same as the shape of the rim of the bottom steel frame.

The specific number of H- shaped steel should be determined according to the actual size of the round furnace bottom steel frame, to ensure that it can be evenly distributed on the periphery of the steel frame, so that the entire furnace shell is evenly loaded. Welding is preferred for the connection between the H- shaped steel and the furnace bottom steel frame and furnace mouth reinforcement ring.

H- shaped steel as the furnace shell mainly considers the excellent mechanical properties of the H- shaped steel itself, such as wide lateral rigidity and strong bending resistance, which can effectively prevent the stress and deformation of the lining and strengthen the overall structure of the induction furnace; Compared with the cylindrical steel plate furnace shell, the H -shaped steel structure is simple and light, so the whole installation process of the furnace shell is relatively simple. Finally, the H- shaped steel is kept at a fixed interval, which is convenient for the maintenance of the induction coil and the yoke inside the furnace shell.

BRIEF DESCRIPTION

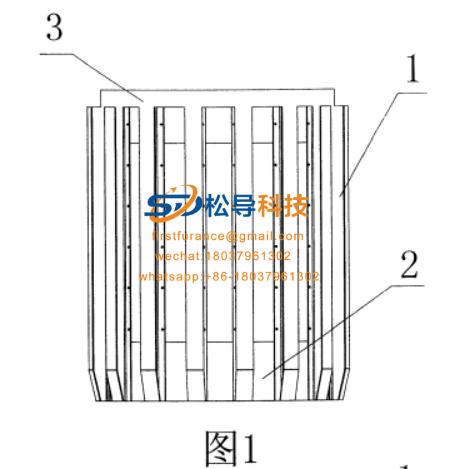

FIG. 1 is a schematic structural diagram of a specific embodiment of the utility model.

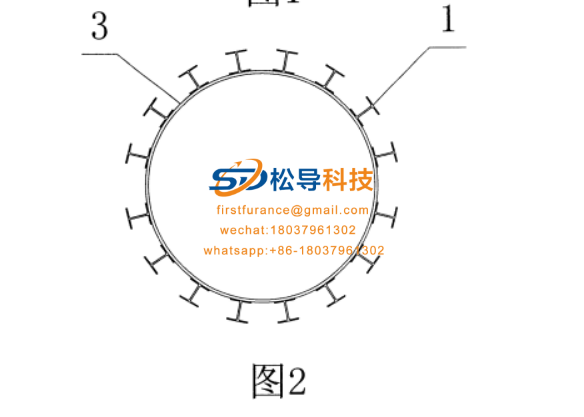

FIG. 2 is a top view of FIG. 1 .

. 1 , H -shaped steel; 2 , bottom steel; 3 , the furnace opening reinforcement ring;

High strength, rigidity induction melting furnace, the furnace shell DETAILED DESCRIPTION

The specific implementation of the present invention will be further described with reference to the drawings. As shown in the specific embodiment shown in FIG. 1 ,

16 root H -beam 1 the lower end is welded a circular steel hearth 2 on the periphery, and adjacent two H -shaped steel holder Room Room

The same. The upper end of the H- shaped steel is welded to the periphery of the same round furnace stiffener ring 3 to stabilize the overall structure.

Like the existing induction melting furnace , the induction coil and yoke are arranged in the furnace shell, and the interval between the H- shaped steels facilitates their maintenance. While the H -beam itself superior mechanical properties to the furnace shell to bring a better carrying capacity and rigidity,

The overall structure of the induction melting furnace is effectively strengthened .