1. IF power supply configuration:

SCR: British Sima, the current and voltage reserve coefficient ≥ 2 times the withstand voltage 2500KV.

Constant power output, automatic adjustment, power factor ≥0.98, output power 10%-100% adjustable.

Fault display and fault self-diagnosis function.

With harmonic elimination measures.

Three-phase full control bridge rectification.

With boost compensation line.

Double closed-loop regulation of current and voltage, with overvoltage, overcurrent, undervoltage, short circuit phase loss protection, and through protection.

Sweep zero-voltage soft start, frequency automatic tracking.

It can be started frequently and the startup success rate is 100%.

Fully digital module control.

Automatic identification of phase sequence.

Internal and external conversion, automatic / manual conversion function.

The thyristor control loop is optically isolated.

The safety factor of inverter and rectifier thyristor is more than 1.5 times.

With operation interlock function.

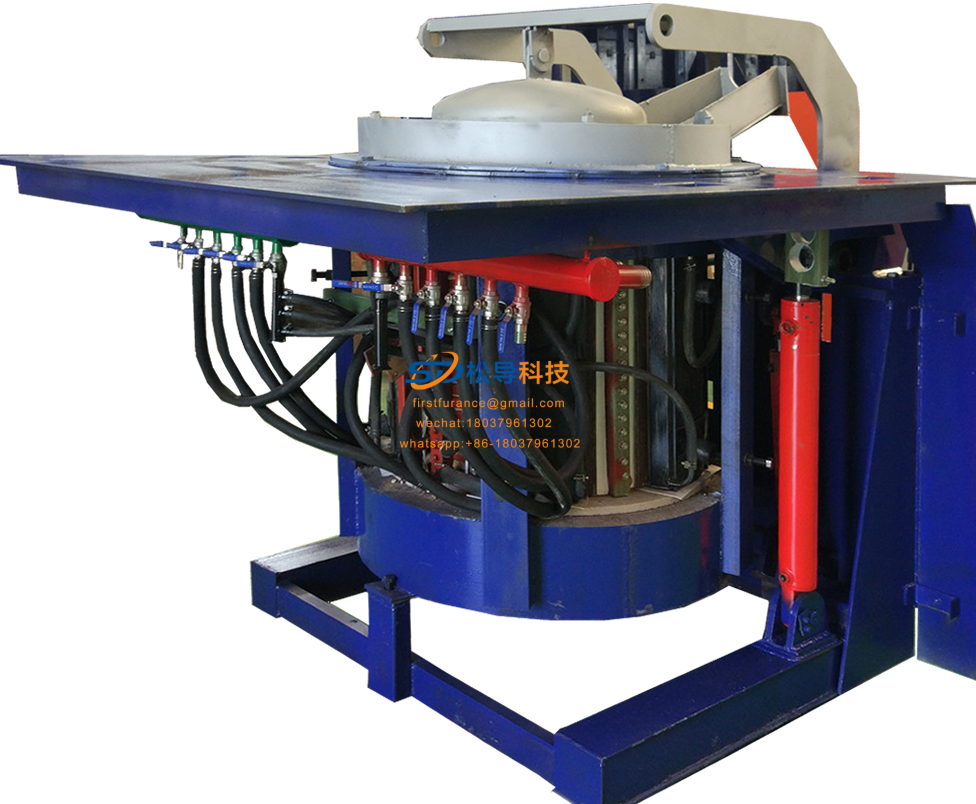

2. Inductive melting furnace dedicated sensor

Copper tube wall thickness δ=5mm

Withstand voltage ≥ 5000V.

With anti-tip discharge measures.

Reliable leak alarm device.

Extended coil, structural lock magnetic ring (short circuit).

The cable adopts the side introduction mode, the path is reasonable, the loss is reduced, and the damage is prevented.

3. Power cabinet

Double door structure, strong and weak electricity.

Protection level indoor IP55, IP65 in the workshop.

4. Hydraulic system

The cylinder is installed upside down and the cylinder rod has guards.

Double machine and double pump are used.

When the furnace body is tilted, it can achieve safe and reliable stop at any position.

Hydraulic cylinders and oil pipes are all domestic high-quality products.

Multi-way valve is used.

5 cooling system

Pumps, water tanks and water pipes are made of corrosion-resistant materials.

Multi-point water temperature monitoring device is set in key parts.

Internal circulation water pressure, water temperature, water quality detection and alarm, and interlock with the induction melting furnace power supply, the pump is ready for use.

The total circulation of external circulation water, the water pressure of the branch pipeline alarm.

Stainless steel plate water-water exchanger, stainless steel pipe fittings, valves.

6 compensation capacitor

With impedance regulator.

Large-capacity non-toxic medium water-cooled medium frequency electric heater.

Temperature detection and over temperature alarm function.

Large section water cooled copper row.

The capacitor housing is double-layered with mica insulation.

The capacitor is directly placed in the cabinet.

The bottom of the cabinet enters and exits the line, and the cooling water pipe enters the side.

Copper busbar and connecting plate thickness δ≥8mm.

7 water-cooled cable

The joint of the water-cooled cable is crimped with a copper strand by a cold press forming process, and can withstand a pulling force of more than 8T.

The outer casing of the water-cooled cable is made of flame-retardant rubber tube and withstand pressure ≥ 0.45MPa.

The copper strand has no broken strands.

8 Change the furnace switch: electric, rated current > 1800A, requires interlocking device with the switch position (integrated with the capacitor cabinet).

9 tilting furnace operating table: furnace body tilting, falling handle, pump station start and stop button, leaking furnace alarm signal.

10 other

5 models, wall thickness δ ≥ 6mm.

The furnace body is tilted at an angle of 95°.

Low-voltage electrical appliances use French Schneider products.

PLC uses the products of American AB.

Appearance color: dark blue.

The thickness of the non-slip steel plate around the induction melting furnace is not less than 8mm.

10′′ color LCD touch screen, AB company products.

Pure water cooling device, Shanghai Haiding products.

The copyright of the article is: http://www.wcdlsb.com All.

http://www.wcdlsb.com/BdwlkjNews.asp?id=650