2019 Nian induction melting furnace prices will jagged reason?

Currently induction melting furnace manufacturers, foundry casting factory during the induction melting furnace price consulting, combined with their own situation, not only to tell the manufacturing induction melting furnace manufacturers themselves how much tonnage of the induction melting furnace , progress note is steel furnace It is also an aluminum shell furnace, a single furnace or a double furnace. The induction melting furnace to be normally connected in parallel is also a new energy-saving series induction melting furnace or a two- induction melting furnace .

The quotation plan provided to the foundry should list the power of the equipment, 6-pulse or 12-pulse intermediate frequency power supply , the common parallel induction melting furnace or the new series of induction melting furnace or one -two induction melting furnace and other detailed parameters, and give the main The model and manufacturer of the components. At the same time, the warranty period commitment is given, and finally the specific offer is given.

When the foundry purchases the induction melting furnace , the first inquiry is required. For the induction melting furnace of the same type and capacity , the prices of many induction melting furnace manufacturers are uneven, sometimes even different. So, what factors determine the price of induction melting furnace ? Rectification copy number, furnace shell, line structure, raw material purchase, sale and decided casting factory in purchasing induction melting furnace time, we must first inquiry, and for the same model, capacity induction melting furnaces , many induction melting furnace manufacturers offer mixed Not uniform, sometimes even very different. Then, what factors determine the difference in the price of the induction melting furnace ? Below we take the intermediate frequency melting furnace as an example to do a simple analysis. 1. First of all, from a technical perspective,

The induction melting furnace is divided into 6-pulse equipment and 12-pulse intermediate frequency power supply equipment. The 12-pulse is stronger than the 6-pulse, and the anti-harmonic interference is stronger, the performance is better, and the price is of course higher.

2, there are the difference between ordinary parallel inverter and series inverter, such as 1 ton ordinary parallel induction melting furnace (old model) and 1 ton series induction melting furnace (1 power cabinet and 1 induction melting furnace ). The 1 ton series induction melting furnace has 1 ton and 2 induction melting furnaces , which will cause great price differences .

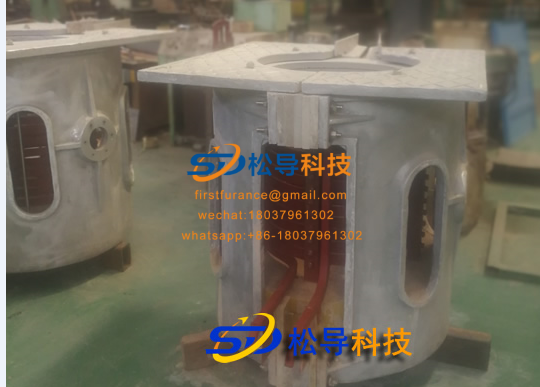

2. Secondly, from the induction melting furnace itself, there is a difference between a steel shell furnace and an aluminum shell furnace. There is also the difference between a single furnace and a double furnace, which will have a great impact on the price of the entire equipment.

3, the power size, the above two conditions are the same, due to the different requirements of the casting manufacturer on the melting rate, the equipment power will be different, of course, the high power price is higher than the low power.

4. Differences in the quality of raw materials and components. When the above three requirements are met , the price difference between raw materials and components of different quality is very large in the process of producing induction melting furnace . Good raw materials and electronic components, long life and low failure rate.

5, after-sales service, quality after-sales is actually part of the price factor.

http://www.songdaokeji.com/plus/list.php?tid=22