Seamless steel pipe quenching and tempering production line

Equipment function: It realizes the functions of feeding, conveying, heating, quenching, tempering and cooling of multi-standard seamless steel pipe.

Equipment technical requirements

Normalizing and quenching temperature 850 ~ 980 °C

Quenching : tube axial surface temperature difference ± 10 ° C, radial ± 5 ° C;

Tempering temperature 550 ~ 720 °C

Tempering : tube axial surface temperature difference ± 8 ° C, radial ± 5 ° C;

Quenched and tempered products meet API standards

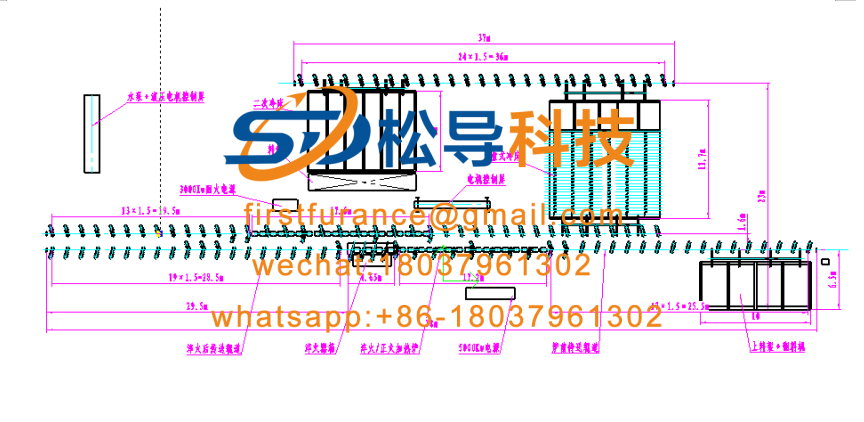

Equipment layout

Quenching, tempering arrangement during quenching and tempering in a line.

, Quenching and tempering line from front to back are: Loading table quenching furnace is about 17.2m 25.5m → → → quenching tank 5m m quench tank to the feed section 29.5m dialed before the tempering furnace conveyor → → Press section 21mThe fire heating furnace is 18m → the tempering and discharging platform is 18m , and the production line is 78 meters in total length .

The layout of the production line is as follows:

2. The positive cooling bed and the secondary cooling bed are arranged on the side of the production line.

3, applicable steel pipe varieties

Oil casings and tubing.

Processing steel pipe type: seamless steel pipe, petroleum oil pipe. Production capacity: 12 tons / hour