1. Automatic control process

Firstly, the process parameters are set on the industrial computer, (transmission speed, target temperature, workpiece specification). The industrial control machine automatically calculates the power value required for the workpiece to heat to the target temperature at a certain transmission speed. The workpiece is manually placed on the feed roller to enter the automatic control state, and sent to the sensor through the transmission mechanism. When the photoelectric switch of the sensor inlet detects that the workpiece has entered the sensor, the intermediate frequency power supplyautomatically starts to the required state. Power value. When the outlet thermometer detects the actual temperature and the target temperature, the power is finely adjusted to achieve the purpose of automatic temperature control. (The specific idea of temperature control: the data obtained by the average temperature calculation of the data measured by the outlet thermometer is 10 times as the basis for calculating the target temperature. When the temperature is higher than the target temperature, the power will automatically drop; when the temperature is lower than the temperature The power will rise automatically at the target temperature. The power adjustment range is based on 1% . This can greatly improve the accuracy of temperature control. The function of control calculation is completed by PLC , and the specific data is displayed on the industrial computer.) After the workpiece exits from the intermediate frequency heating furnace Directly enter the resistance holding furnace, the holding furnace is divided into six sections, the third section is equipped with a thermocouple temperature measuring device, and the temperature in the holding furnace is automatically controlled by the temperature signal of the feedback of the thermocouple. The target temperature can be directly performed on the industrial computer. Input. After coming out of the holding furnace, it enters the air-cooled gantry. When the temperature measured by the thermometer reaches the air-cooled set temperature, a prompt signal is issued. At this time, the artificial hand adjusts the anti-deformation device to start the workpiece in the transfer roller of the air-cooled gantry. Device.

2. The functions realized by the automatic control system:

2.1 Stable and reliable temperature closed-loop control, real-time acquisition, recording, and storage of process control data with corresponding classification and retrieval. Production data is entered in recipe mode.

2.2 Real-time detection of process control effects; in the process of equipment operation, real-time analysis of the monitoring and monitoring device's follow-up state, timely prompts for various abnormal conditions, and sound and light alarm.

2.3 Convenient and quick operation mode conversion (just switch the "automatic" "manual" switch on the console to switch between the two.

2.4 According to the needs, the operator can be used to set the password password verification function, production record query and management functions.

2.5 Clear and friendly operation interface, all kinds of operations at a glance, you can get started without having to memorize the complicated operation rules.

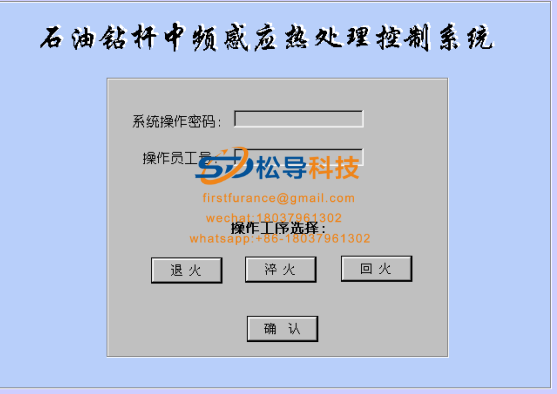

3 automatic control system man-machine interface:

The following is the self-control interface of our company in the medium-frequency heat treatment production line of oil drill pipe for reference.

3 . 1 system startup interface: