1,Equipment overview

Induction melting furnace is an efficient smelting equipment that melts scrap steel by electromagnetic induction heating. The energy conversion process is electro-magnetic-electric-heating, in particular, the power frequency power supply outputted by the rectifier transformer is converted into a single-phase AC power source matching the required frequency of the load in an AC-DC-AC mode, and is generated in the steel scrap in the furnace. High-strength magnetic field, the steel scrap in the furnace induces a strong electric field under the action of a magnetic field and forms an internal eddy current, thereby forming a heat source to melt itself. This heating method of generating thermal energy by itself inside the charge is an efficient way of melting.

The Induction melting furnace produced by our company has the following characteristics:

1 The input voltage is high and the output voltage is high. For the rated capacity of this program 30t Induction melting furnace, our company is designed according to the 1750V incoming line voltage specification, and the sensor load output voltage is nominally 6300V.

2 High melting rate. The rated design tonnage tapping amount is reached, and the continuous hot furnace smelting time is controlled at about 75 minutes.

3 tons of steel has low energy consumption. It is 5% lower than other manufacturers' equipment, which is better than the first-class standard in GB/T30839.31-2014 "Industrial electric heating device energy consumption: medium frequency centerless Induction melting furnace".

4 Digital, integrated, and highly automated. The company's power system control board is a digital chip type control board. The power amplifier board is an integrated control board integrating power amplification, vulnerability detection and output. The smelting management system realizes the monitoring and management of the entire equipment by using S7-300PLC+ high-equipped host as hardware and STEP7+WINCC as software.

2,Technical solutions and technical parameters

2.1, Technical solutions

For the 30t Induction melting furnace of this project, the company adopts the following technical solutions:

▷ Equipment configuration mode: one electric two furnaces. A furnace is normally smelted, and a furnace is used for furnace maintenance.

▷ Switching mode: mechanical change of furnace switch.

▷ Feeding method: The hydraulic feeding trolley on the platform is fed after the furnace.

▷The method of steel tapping: hydraulic tilting furnace, tapping nozzle and tapping steel tapping.

▷ Transformer: A single 24-pulse rectifier transformer is used.

▷Automatic control system: The hardware adopts S7-300 and configures industrial control computer.

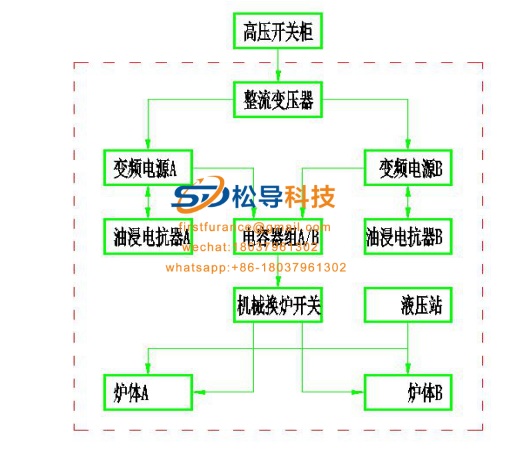

The equipment system diagram is as follows:

高压开关柜:High voltage switchgear

整流变压器:Rectifier transformer

变频电源:Frequency change power

油浸电抗器:Oil immersion reactor

电容器组:Capacitor bank

机械换炉开关:Mechanical furnace change switch

炉体:Furnace body

液压站:Hydraulic station

2.2、Technical parameters

ITEM | UNIT | PARAMETER | REMARK | |||

Basic parameters | ||||||

Rated capacity | t | 30 | ||||

Max capacity | t | 40 | Depending on the furnace building process | |||

Rated tapping temperature | ℃ | 1600 | ||||

Melting time | min | 75±5% | Note1 | |||

Melting rate | t/h | 23-25 | Note1 | |||

Power consumption | KW·H/t | 500±5% | Note1 | |||

Frequency change power | ||||||

Rated power | KW | 16000 | ||||

Inlet voltage | V | 1750 | mid-gear | |||

Rectification mode | P | 24 | ||||

Mid-frequency | HZ | 150 | ||||

Output voltage | V | 6300 | ||||

Cyclic mode | Closed (internal and external double cycle) | Cooling water | ||||

Pressure | MPa | 0.1-0.12 | Outlet≤0.05 | |||

Flow | t/h | 260 | ||||

Inlet temperature | ℃ | ≤35 | ||||

Temperature raise | ℃ | ≤8 | ||||

Induction melting furnace body | ||||||

Inner diameter of inductor | mm | φ1900 | ||||

Height of inductor | mm | 2900 | ||||

Voltage of inductor | V | 6300 | ||||

Cyclic mode | Closed (internal and external double cycle) ; Can choose to open | Cooling water | ||||

Pressure | MPa | 0.2-0.3 | ||||

Flow | t/h | 450 | Single furnace 300 | |||

Inlet temperature | ℃ | ≤40 | ||||

Temperature raise | ℃ | ≤12 | ||||

Hydraulic system | ||||||

Working pressure | MPa | 12 | ||||

Hydraulic medium | Flame retardant anti-wear hydraulic oil N68 | |||||

Diameter of cylinder | mm | 280 | ||||

Rectifier transformer (single set 24 pulses, with electrostatic shielding and secondary low voltage relay protection) | ||||||

Rated capacity | KVA | 21000 | ||||

Reference model | ZSSP-21000/22 /1.75*4 | |||||

First line voltage | KV | 22 | Reference temporarily | |||

Second line voltage | V | 1750 | mid-gear | |||

Impedance voltage | >10% | |||||

Adjust voltage mode | Non-excitation voltage regulation | |||||

Cooling mode | Forced oil circulation water cooling | |||||

Cyclic mode | Closed (internal and external double cycle) | Cooling water | ||||

Pressure | MPa | 0.1-0.12 | ||||

Flow | t/h | 60 | ||||

Intlet temperature | ℃ | ≤35 | ||||

Temperature raise | ℃ | ≤8 | ||||

NOTE 1:

Users working conditions:

Scrap steel yield ≥97%, hot, continuous, light and thin materials must be packaged into briquettes, large material cutting, with the use of pressing manipulator. Except for heat preservation and slag discharge time, based on the actual weighing of molten steel.