1 , an induction melting furnace is a three-phase frequency inverter unit currents into a single-phase current of the intermediate frequency, the electromagnetic field induced by the metal, the eddy current loss, and achieve the purpose of heat melting. It is used for melting, heating and heat preservation of black or non-ferrous metals and alloy materials such as steel, copper, aluminum, zinc and lead. Mainly used in metal casting, steelmaking industry.

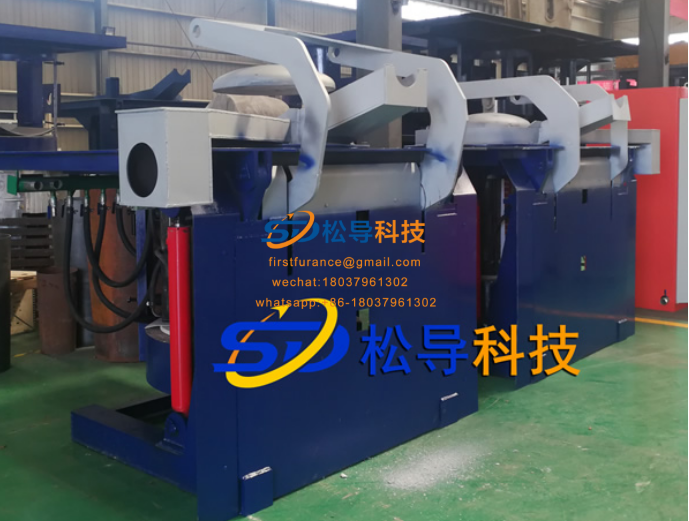

2 , furnace structure ( steel shell furnace and aluminum shell furnace )

Aluminum shell furnace body; aluminum shell, induction coil , reducer

The steel shell furnace body includes: a steel shell furnace body , an induction coil, and a magnetic field shielding system . Three major parts

The configuration parts include: automatic oven function , cyclone type dust cover , furnace change switch, anti-drop device, leakproof furnace alarm device, furnace lining quick-release mechanism, furnace body weighing system .

★ Cyclone dust hood: It has better vacuuming effect, takes up less space, can tilt forward and backward and stay in any position. Applicable to the fully automated feeding and discharging operations of the foundry.

★ Changer switch: The changeover switch is an electric quick change switch used in medium frequency electric furnace: easy to operate, safe and reliable, easy to use, shortens the time of furnace switching, improves efficiency, reduces labor intensity of workers, and can It is easy to realize the switching of the intermediate frequency power supply to the holding furnace body and the melting furnace, which has great practicality.

★ Anti-wearing furnace alarm function : double anti-wearing furnace alarm function, using dual combination detection of differential current mode and DC injection type. Provides an extremely reliable leak protection for the furnace system and all-round rapid protection of any ground fault. The detection system has an early warning function. When the furnace lining is thinned to a certain extent, an alarm light alarm will be made in advance to remind the user that the life of the lining will be reached, and the purpose of safe production is predicted in advance. Solve the trouble of the customer because it has been used until it can not be turned on, and the furnace has material and cannot continue to melt.

★ Furnace lining structure: Once the furnace temperature is cooled to below 400 °C, the furnace body is turned to 90 degrees, the crane is lifted and pushed out, and the cylinder connection flange is placed in the pre-designed rail at the bottom of the furnace body to start the hydraulic pump station. , easily launch the lining. Reduced work intensity and improved work efficiency.

IF power performance characteristics:

According to the size of the power , the induction melting furnace can choose KGPS intermediate frequency power supply , 12 pulse wave intermediate frequency power supply and 24 pulse wave intermediate frequency power supply , and can also select IGBT intermediate frequency power supply . The control mode of the IF power supply can be designed as local control, touch screen control, remote control, and computer control.

Induction melting furnace technical parameters :

Induction melting furnace model | GWGR - 1 | GWGR -2 | GWGR -3 |

Rated capacity (T) | 1 | 2 | 3 |

Power ( KW ) | 1000 | 1500 | 2000 |

Frequency ( Hz ) | 1000 | 800 | 800 |

Rated temperature (°C) | 1650 | 1650 | 1650 |

Melting time (minutes / furnace) | 60 | 60 | 80 |

Power consumption ( kwh/t ) | 550~600 | 550~600 | 550~600 |

Cooling water pressure | 0.2~0.3M p a | 0.2~0.3M p a | 0.2~0.3M p a |

Inlet water temperature (°C) | ≤ 35 | ≤ 35 | ≤ 35 |

Outlet water temperature (°C) | ≤ 55 | ≤ 55 | ≤ 55 |

Related Products:

1 ton induction melting furnace

2 tons induction melting furnace

3 tons induction melting furnace

5 tons induction melting furnace