A kind of low-zinc and low-magnesium mixed rare earth metal is used as a raw material, and an alkali metal chloride is used as a protective agent to melt the negative electrode mixed rare earth metal of the battery in an induction melting furnace , which belongs to the field of metallurgy.

Currently, the battery negative mischmetal rare earth is low low magnesium zinc chloride as raw packets, using 2000A electric

Produced by the solution tank, the technological parameters of each group of electrolytic system (current, voltage, temperature, electrolyte concentration) are not the same, and the grouped rare earth chloride can not complete the content of the batching elements between each batch during the production process Consistent. Due to the limitations of the production process conditions of raw materials and equipment capabilities, the content of lanthanum, cerium, praseodymium, and neodymium in products fluctuates greatly, especially lanthanum is the most serious, which will directly affect the service life of the end product nickel-hydrogen battery.

The purpose of this method is to provide a process for melting the mixed rare earth metal of the negative electrode of the battery using an induction melting furnace ,

It is a component element of the mixed rare earth metal that stabilizes the negative electrode of the battery , and uses a binary mixed salt of potassium chloride and sodium chloride as protection

Covering agent, which can prevent the oxidation loss of rare earth metals, and achieve uniformity of the proportioning elements in mixed rare earth metal products.

To.

The process of induction melting furnace to melt the battery negative mischmetal process for, in a non-open system vacuo

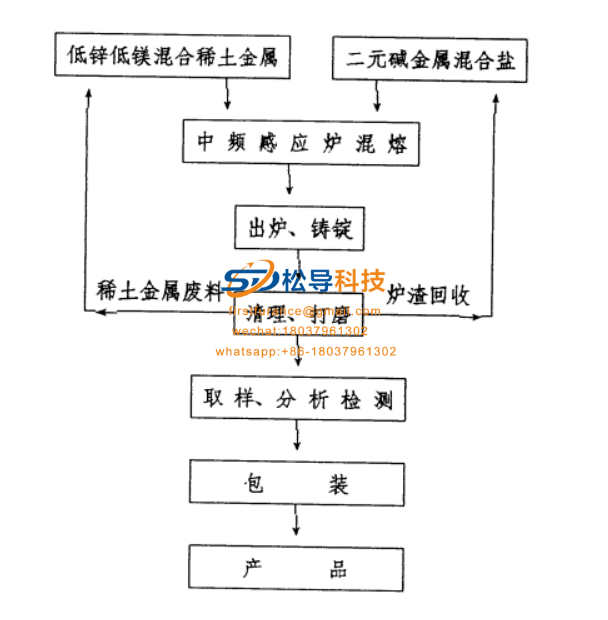

It uses low-zinc and low-magnesium mixed rare earth metals as raw materials, uses potassium chloride and sodium chloride binary mixed salt protective covering agent, and uses high-purity alumina ceramic crucibles as the smelting vessel to melt the mixed rare earth metals of the battery anode . In the process of ingot, the split bottomless casting ingot mold is used. After heating and melting the binary mixed salt of potassium chloride and sodium chloride, slowly add the specified batch of low-zinc and low-magnesium mixed rare-earth metal, and after melting, through the stirring effect of the induction melting furnace itself, the liquid rare-earth metal is fully mixed evenly. The smelting temperature is 850-950 ℃, the smelting time is 20-40 minutes, the ratio of mixed rare earth metal and protective covering agent is 3-5: 1 , so that the internal ingredients of the product are uniform. Reduce vacuum equipment and equipment investment. The smelting vessel and induction melting furnace are sintered with quartz sand between the induction coil and the crucible to protect the furnace body and the crucible, and 3-5% boric acid is added to the quartz sand to increase the density of the furnace lining. The protective covering agent uses a binary mixed salt of potassium chloride and sodium chloride, which can reduce the melting temperature. When mixing rare earth metal ingots, it ensures the appearance quality of the rare earth metal ingots and reduces the loss of rare earth metals in the melting process. In the process of ingot casting, a split bottomless ingot mold made of heat-resistant steel is used. After the casting is completed, after the temperature of the rare earth metal decreases, take

The lower ingot makes the rare earth metal easy to demold, and the service life of the bottomless ingot mold is long, while reducing labor intensity.

The process of induction melting furnace negative battery melting mischmetal production process is simple, user-friendly production operations, consistent with the internal parts of a rare earth element content of the product, the ratio in favor of the production of the raw material powder, nickel-hydrogen, rare earth metals and less investment in equipment, It is easy to install and maintain, the content of non-rare earth impurities in the product is low, and the product quality is stable, thereby improving the performance of the nickel-hydrogen battery. The quality of the melted product can fully meet the user's requirements.

4. Specific implementation methods:

The best embodiment of the method of the induction melting furnace for melting the mixed rare earth metal of the negative electrode of the battery in this method :

Raw materials: 197 tons of mixed rare earth metals with low zinc and low magnesium

KCI-NaCI = Yuan mixed salt 18 tons

Equipment: GW- 0 . 5T intermediate frequency coreless induction melting of the furnace

Production process: Put 20-25Kg = Yuan mixed salt in each furnace (industrial-grade Baotou production), add it after melting

The 250-255Kg low zinc low magnesium misch metal (header, Ltd.), induction melting furnace power adjustment main 100KW or so, the temperature

Maintain at 850-950 ℃, smelt for 20-30 minutes, let stand for 5 minutes, wait until its internal ingredients are fully uniform

Furnace, casting operation, use a stainless steel spoon to take out the metal and cast it in the bottomless 42CrMo ingot mold, and then proceed

One furnace smelting operation, after the metal is cooled, it is demoulded, cleaned and polished, and it is packaged after passing the analysis and inspection

For the final product.

Test result: The product is battery negative electrode mixed rare earth metal 194. 35 tons, power consumption is about 420Kw . h / t , analysis

The test results show that the internal components of the product are even and stable after melting , and the non-rare earth impurities do not exceed the standard.

The content of the ingredients in the product is uniform.

Analysis results of any five rare earth metals in the same batch before melting (%) Table 1

Analysis results of five rare earth metals in the same batch after melting (%) Table 2