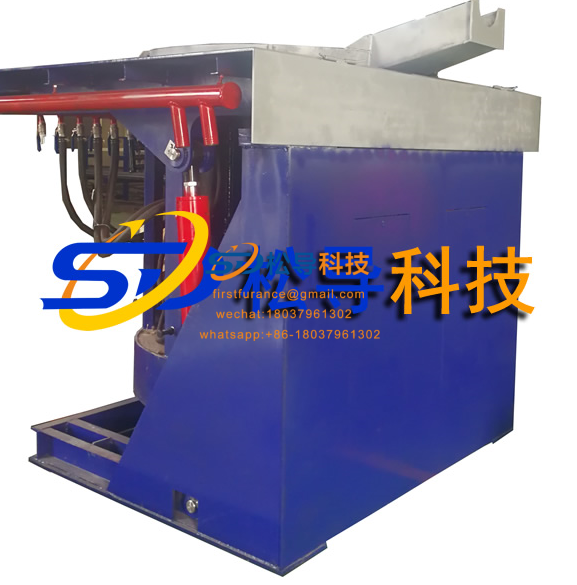

Equipment Description: IF coreless induction melting furnaces for steel and iron foundry melting work.

This equipment is a power-saving product, which features fast temperature rise, low energy consumption, and stable and reliable operation. The 1 ton intermediate frequency heating furnace ( new 2020 ) mainly consists of an overload rectifier transformer 800kva, a 1000kw series intermediate frequency power supply, a steel shell furnace, and a PLC-assisted melting management system. The PLC-assisted melting management system can not only display real-time data and information of power supply operation, but also display the operating status and information of the entire system. It also has automatic oven, cold furnace startup, fault diagnosis, fault information display and storage, and operation information display. , System status display and other functions.

Basic configuration: one 800kva 6-phase 12-pulse transformer (full output is 1000Kva), one furnace body, one series IF power supply, one set of inverter compensation capacitor, and the power supply structure is a 6-phase 12-pulse dual rectifier series inverter structure . A hydraulic tilting furnace inversion mode, with far range manipulated box.

1 ton induction melting furnace technical parameters

Device model GWT-1 / 1000 | Technical indicators (12 pulses) |

IF power supply rated power | 1000KW frequency 1000Hz |

Line voltage | 6 * 380V, 6 * 660V |

Rectification method | Double rectification |

Inversion method | Single inverter series |

IF voltage | 3000V |

Rated Capacity | 1T |

Rated temperature | 1800 ℃ |

With IF power supply specifications | KGPS-1 / 1000 |

With intermediate frequency induction melting furnace specifications | GW-1 steel shell , GW-1 aluminum shell |

Melting rate | 1T / 50 minutes |

Power factor | ≥0.95 |

Tilting method: | Hydraulic |

Water-cooled cable | Four |