China manufacturing 2025 future single pillar pillar quenching and tempering production line design

Process requirements: design

l, material: 27SiMn;

2. Specification length (mm):

Specifications (diameter wood length): diameter 114: length: 1040

Wall thickness: 9mm

3. The cylinder is heated to the quenching temperature by the intermediate frequency power supply, then cooled and quenched, and tempered online.

Quenching heating temperature: 930--950 °C

Tempering heating temperature: 520 ~ 550 ° C

Second, the overall design overview:

1. The cylinder quenching and tempering treatment is actually a quenching and high temperature tempering composite heat treatment process.

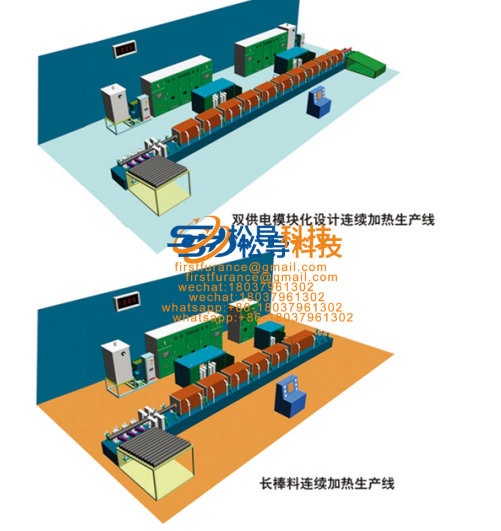

The traditional treatment is carried out by electric resistance furnace, which has the disadvantages of low production efficiency and poor quality stability. According to the characteristics of steel pipe, our professionally designed steel medium frequency quenching and tempering production line has been successfully applied to the quenching and tempering of single cylinder, oil pipe and hydraulic pipe. Heat treatment, the quality is stable and reliable, the production efficiency is increased by 2 to 3 times, and obvious economic benefits are obtained. The complete production line is mainly composed of a mechanical conveying device, an intermediate frequency quenching heating module, an intermediate frequency tempering heating module, a closed cooling system, an infrared temperature measuring device, a quenching cooling device, and a main console. The mechanical conveying device comprises a storage platform, a turning rack, a track feeding device, a straightening machine and a unloading frame. The quenching and heating process of the cylinder adopts intermittent heating, and the tempering heating adopts continuous heating; the temperature is uniform and the deformation is reduced.

2. About the selection of thyristor intermediate frequency power and frequency:

Equipment power and operating frequency are the most important technical parameters. The production quantity determines the equipment power, and the effective thickness of heating determines the working frequency:

Quenched with SCR frequency power supply power selection

Serial number | Material specification | weight | Heating beat | Heating temperature | Operating power | Design power | Single quenching power consumption |

1 | Diameter 114X1040 wall thickness 9mm | 25 kg | 55 seconds | 930 | 480 | 500KW | 7.4 degrees |

Tempering with SCR frequency power supply power selection

Serial number | Material specification | weight | Heating beat | Heating temperature | Operating power | Design power | Single quenching power consumption |

1 | Diameter 114X1040 wall thickness 9mm | 25 kg | 55 seconds | 550 | 280kw | 300KW | 4.4 degrees |

http://www.songdaokeji.com/plus/view.php?aid=340