Steel pipe quenching and tempering production line

Introduction

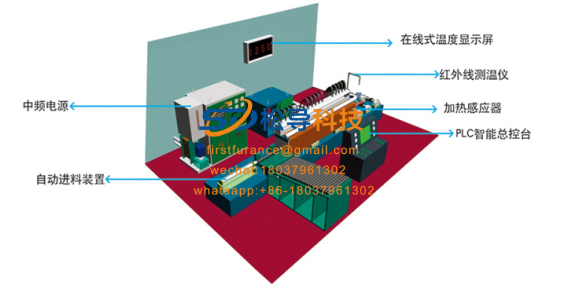

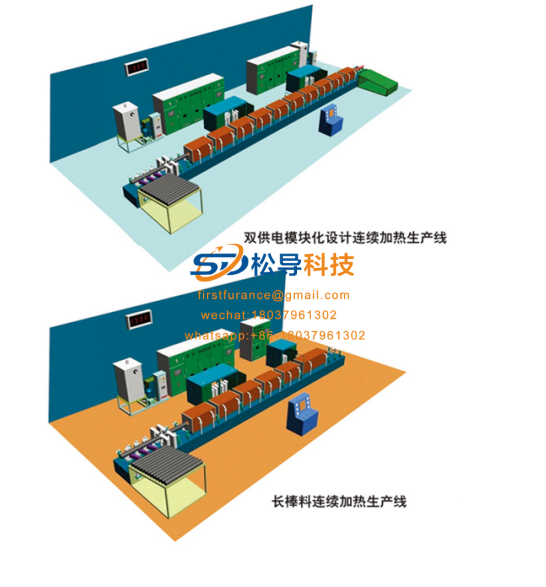

The mechanical transmission device for quenching and tempering steel pipe adopts a single-station method, medium-frequency quenching and medium-frequency tempering, and annealing is performed in a time-sharing manner. The replacement of the sensor adopts integral lifting, rapid positioning, and quick connection of water and electricity (the replacement of one sensor can be completed in a short time). The position of the sensor axis can be easily adjusted to meet the heating requirements of various steel pipe specifications. According to the needs of each product, this set of steel pipe quenching and tempering production line consists of inlet and outlet material storage bracket, feeding and discharging conveying device, workpiece spin roller conveyor, medium frequency quenching heating module, medium frequency quenching and heat preservation module, intermediate frequency tempering module and intermediate frequency. The annealing module, the quenching spray device, the hydraulic station, the center console and the automatic control system are composed of eleven parts.