First, heating process and technical requirements

1.1 Use: matched with 2500 ton press, forging the billet of the front axle of the car;

1.2 Workpiece material: medium carbon steel

1.3 Heating temperature: 1250 ° C

1.4 Temperature difference requirements: radial temperature difference ≤ 60 ° C , first and last temperature difference ≤ 80 ° C ;

1.5 Heating part: overall heating

1.6 Typical blank size:

Optional power | product name | Specification range Mm | Weight per section Kg | Beat s | productivity Kg/h | Configuring the sensor Model |

500kw×2 | Car front axle | Φ 16 0 × 800 | 126.2 | 180 | 2524 | GTR-19 0 × 2500 × 2 |

[Note]: According to the requirements of the factory, two sets of 500kw combined heating method.

Second, the overall design plan overview:

2.1. Power: The total frequency of the 2 intermediate heating furnaces is 1000KW, and the nominal frequency is 500hz.

2.2. Configure the sensor model and structure: GTR-190×2500, the basic parameters are as follows:

Configuring the sensor Model | Furnace inner diameter Mm | length Mm | Furnace lining material | Load power Kw |

GTR-19 0 × 2500 | 190 | 2500 | Knotted lining | 450 |

2.3. Furnace structure: According to the requirements of the factory, the furnace body is made into double working position, each station is 500kw, combined heating, staggered one time between them, complementary feeding, alternating discharging, combined heating time of 180 seconds The beat when running alone is 360 seconds.

2.4. Material preparation method: The ground hoist is used to lift the blank to the storage rack. The storage bin can store 4 materials at a time;

2.5, feeding mode: using cylinder pushing material, step feeding method;

2.6. Discharge method: the discharge end uses roller conveyor to pick up the blank;

2.7. Temperature detection and sorting: The infrared burner is equipped with an infrared thermometer to perform three-point selection on the ultra-high temperature, ultra-low temperature and normal temperature of the billet.

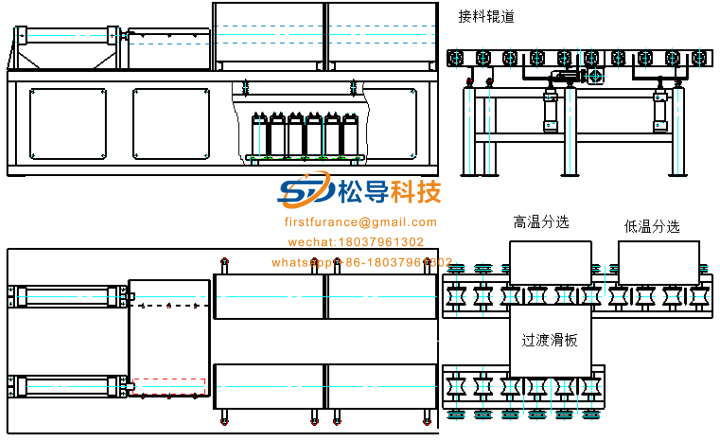

2.8. The overall structure is as shown in the figure:

Third, the power supply transformer:

3.1. The transformer that supplies power to the two intermediate frequency furnaces must be a dedicated rectifier transformer. This is because the high-power inverter will generate harmonic pollution to the power grid because the rectifier transformer uses Y/△ connection method, valve side Y-12 and △-11. The phase difference of the line voltages is 30 °, so that the Y group rectification and the Δ group rectified voltage ripple of the two intermediate frequency power sources also have a phase difference of 30 °, and the two sets of six-phase pulse waves synthesize a 12-phase pulse wave. The combined current waveforms of the two current waveforms in the transformer network side winding can effectively suppress the generation of the 5th and 7th harmonics .

3.2 , the connection diagram of the rectifier transformer and two intermediate frequency power supplies:

3.3 , ZS-1250-10/0.38 rectifier transformer technical parameters:

l Rated capacity: 125 0KVA; rated voltage on the grid side: 10 ± 5% (KV) 3 Φ/ 50HZ

l Valve side I rated capacity: 625 (KVA)

l Valve side I rated output voltage: 38 0 (V)

l Valve side II rated capacity: 625 (KVA)

l Valve side II rated output voltage: 38 0 (V)

l Connection group: D do yn11 ;

l Impedance drop: Uk=7%

l Shield between the mesh side and the valve side to reduce the impact of harmonics on the mesh side.

l It has the advantages of low loss, high reliability, low noise and low temperature rise.

l With light gas alarm, heavy gas trip; oil temperature alarm, trip; pressure release and other protection.

3.4, the technical standards adopted by the transformer:

l GB/T18494.1—2001 «Industrial converter transformer»

l JB / T8636—1997 «Power converter transformer».

Fourth , the water cooling system of the intermediate frequency furnace:

4.1. Cooling water is the “life” of the intermediate frequency furnace. When the hard water is heated, it will easily cause dirt to block the pipeline. It is therefore recommended that the IF power cabinet and capacitor section be cooled by a soft water cooler.

4.1. Cooling water is the “life” of the intermediate frequency furnace. When the hard water is heated, it will easily cause dirt to block the pipeline. It is therefore recommended that the IF power cabinet and capacitor section be cooled by a soft water cooler.

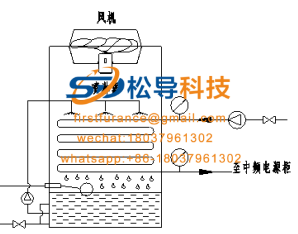

4, 2, FL-350B closed cooler: This cooling unit can be used to cool two 50 0kw intermediate frequency power supplies at the same time . It uses pure water (softened water) as the cooling medium, a serpentine copper tube as the radiator, and fully enclosed circulating water. The heat is taken away by the action of the fan, and if necessary, the cooling effect can be enhanced by spraying water through the sprayer. The water return temperature sensor is installed with a water temperature sensor, and the whole process can be controlled during the operation. Its cooling principle is as shown in the figure:

4 . 3, FL- 3 50B soft water cooler technical parameters:

model | cool down Ability kcal/h | jobs Water pressure M pa | jobs flow M3/h | In and out Pipe diameter Mm | rated power Pump/fan Kw | Water tank capacity Kg | shape size m | weight Kg |

FL-350 | 105000 | 0.25 | 12-25 | DN50 | 1.1 / 3.0 | 400 | 3.1×1.1×2.0 | 1080 |

4 . 4 cooler package range:

l 1 set of housing (galvanized panel)

l Cooler 1 set (copper tube)

l Fan 1 (aluminum alloy blade)

l spray pump 1 set

l Set sink 1 set (stainless steel material)

l 1 set of dehydrator (made of PVC material)

lMain water pump 1 set

l Stainless steel circulating water tank 1 ( 0.5M 3 )

lElectric control box 1 set (with temperature control system)

4 .5 , external circulation water cooling system: The external circulation water system includes equipment such as circulating pool, water pump and pipeline gate valve , which is specially used to cool the induction coil. The equipment and facilities are built by the user . Technical indicators of external circulation water :

Cooling water inlet temperature : 5 ~ 35 ° C

Cooling water outlet temperature: ≤ 55 °C

Cooling water pressure: 0.30Mpa ~ 0.40MPa

Water supply (pump flow): 18 m 3 /h (total of two furnaces)

Return pipe slope: i=0.01

Cooling water quality requirements :

PH value: 7 ~ 8.5

Total hardness: ≤10 degrees (to 1 liter of water containing 10 mg of CaO)

The effective volume of the cooling water pool is not less than 50m 3 . (for two stoves)

Five , the machine performance:

◇ System power factor: At full voltage, the power factor reaches 0.92;

◇ oxidation and decarbonization: billet heating oxidation loss is not greater than the diameter of the billet 0.3 %, the surface decarburized layer depth not exceeding 0.3 mm.

◇ Energy consumption: no more than 370kw.h/t when the load and the workpiece are optimally coupled;

◇ Startup performance: 100% success rate for hot, cold, no-load or full load start;

◇ Short-circuit protection: When the load is short-circuited, the heating system can be reliably shut down and protected, and will not cause damage to various components;

◇ Water temperature protection: Induction coil, intermediate frequency power supply and capacitor are equipped with water temperature sensor. When the circulating water temperature exceeds the rated temperature, it can alarm immediately or automatically turn off the intermediate frequency power supply;

◇ Safety protection: There is no liquid or gas leakage in the whole machine. The housing should have reliable grounding protection. For the place that is easy to cause safety accidents, there should be a protective cover with a prominent safety mark.

◇ Noise: less than 8 0db

◇ Appearance quality: beautiful appearance, bright paint, strong welding, thorough rust removal, smooth surface smoothing, reasonable spacing of all parts, clear edges and corners, clear color standard, flexible door leaf opening, beautiful appearance .

Sixth, thyristor intermediate frequency power supply cabinet

. 6 . . 1 , KGPS-500 / 0.5 frequency power supply main technical parameters as follows:

Model | Rated power Kw | Nominal frequency Hz | Input voltage V-phase number | Input Current A | DC Voltage V | Intermediate frequency Voltage V | Intermediate frequency current A | Remarks |

KGPS-5 00/0.5 | 5 00 | 500 | 38 0V- 3 N | 90 0 | 50 0 | 7 00 | 110 0 | Single rectifier line |

. 6 . 2 , the BSC 8M -2 MPU : the core components of a high-density integrated circuit ASIC2 U.S., adaptive phase sequence circuit, an inverter using Sweep zero-pressure start mode using the average sampling frequency tracking circuit scheme, An inverter angle adjustment circuit is added to the inverter circuit, which automatically adjusts the matching of the load impedance. With heavy-duty start and lack of material protection.

. 6 . 3, the function of protection: The MPU core digital circuit channel 31 has input / output interface, the internal phase trigger function includes a rectifier, an adaptive phase sequence, trigger inverter, the inverter before the lead angle lock, start repeating the inverter And the main control board undervoltage automatic protection and other functions.

◇ Main circuit short circuit protection

◇ Main circuit phase loss protection

◇ High voltage and low protection

◇ Cooling water pressure low protection

◇ Cooling water temperature protection

◇ SCR overvoltage, overcurrent protection

◇ Load overvoltage, overcurrent limit

. 6 . . 4 , filter reactor: Reactor selected Wuhan silicon is produced by cold rolling a high permeability silicon steel Z10. The copper tube is wound with T2 oxygen-free copper tube produced by Luoyang Copper Material Factory. Double winding wire package, mica tape banding, Class H insulation, noise below 70 decibels during operation ;

. 6 . . 5 , circuit breaker: frequency power supply pre-selection of the circuit breaker switchgear model DW-17 ;

. 6 . . 6 , the operation panel: Panel DC voltage, DC current, intermediate voltage, the intermediate frequency power, IF frequency with the other block table. It is equipped with AC split/close, medium frequency start/stop, fault reset button, over current, over voltage indicator, internal / external control switch and power potentiometer. The power output of the inverter can be arbitrarily adjusted within the range of 10% to 100%.

. 6 . . 7 , the inverter cooling water protection system: frequency power supply cabinet is closed cooling water , thyristors, the reactor temperature protection installation, when the water temperature exceeds the rated inverter automatically shut down; all incoming and outgoing pipes are made of stainless steel Production.

. 6 . . 8 , the shell structure of the inverter: Overall structure of a standard cabinet GGD, three door cabinet, dimensions (width × height × length): 240 0 × 900 × 20 is 00mm , by spray cabinet housing, The color is light green .

Seven , induction heating furnace part

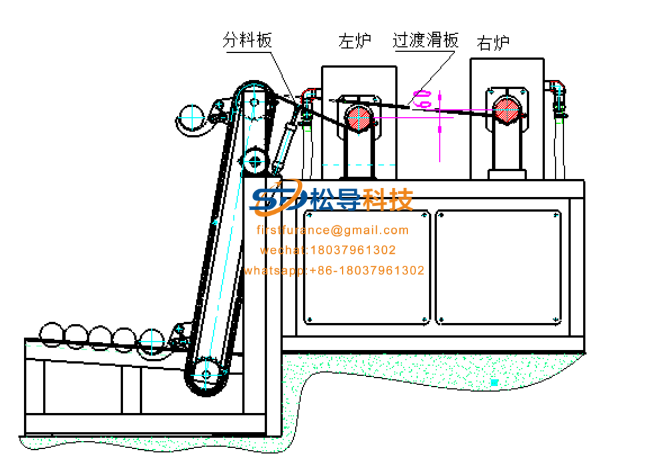

. 7 .1 furnace basic configuration diagram of the mode of operation :( basic configuration see the FIG.) Two sets of 500kw furnace juxtaposed on a capacitor, the load sensors operate independently, can work at the same time, it can also be run separately. When working at the same time, they staggered a time beat between them, alternate feeding, and the tires flow out.

. 7 .2 load sensing parameters: (see Article )

7.3. Basic process requirements for inductor manufacturing:

◇The cooling water pipe is connected by quick-change joints, and the various valves used in the system are stainless steel valves or copper valves;

◇ sense reactor and capacitor banks busbar connection using a bolt connection, reliable and secure connection;

前The front and rear panels of the 采用inductor are made of 8mm thick copper plate and must be cooled by water; the other outer wall panels of the inductor are made of epoxy resin, and the thickness is not less than 10 mm;

The ◇ 器 采用 采用 采用 采用 采用 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛 洛5000V or more;

◇ coil normal use life expectancy ≥ more than 8 years;

◇ Induction coil cooling water uses open back water.

. 7 . . 4 , the lining and the guide rail: lining induction coil silicon carbide lining, the life of the lining under normal use up to 600 hours or more. Each sensor is equipped with a separate water-cooled guide rail, and the surface of the guide rail must be sprayed with a layer of tungsten-cobalt alloy ;

. 7 . . 5 , capacitor cabinet: cabinet has a capacitor and the capacitor between the fixed ceramic base, the second insulation installation, using copper tank . 1 2 0 × [delta] . 4 mm size made of copper, copper between two mica The paper is insulated and the water cooled copper tube is welded. The cooling water hose is made of pressure-resistant plastic hose. All the cooling systems of stainless pipes are made of steel material. The capacitor is equipped with an overheat protection system. Capacitor stent sufficient margin, increases for future transformation capacitor location, the capacitor employing the closed type cooling , water was added protection;

Eight , mechanical devices:

8.1 . Ground hoist: The hoist can be installed in a sinking manner. The storage table is as flat as the floor of the workshop, and the blank is conveniently rolled onto the storage platform. The hoist is equipped with two rows of chains with a spacing of 60 0mm, which is suitable for smooth feeding of 800mm length blanks. The receiving plate at the top of the hoist adopts the movable sliding plate . The sliding plate is operated by the cylinder and has the function of dividing the left and right furnaces. When the blank is distributed to the right furnace, it must be rolled into the pushing tank of the right furnace through the intermediate sliding plate to slow down. The impact force when rolling, the buffer plate is equipped with a buffer device;

8.2 . Storage platform: The ground storage table can store 5 blanks at a time, the table has a slope of 5°, and the blanks are sequentially rolled onto the hooks of the hoist;

. 8 . . 3 , the pneumatic pusher: the maximum stroke of the cylinder . 9 00mm, cylinder stroke can be adjusted according to a random length of the blank.

8.4. Feeding roller path: The roller wheel wheel spacing is 400mm, installed at the discharge end, the motor is driven, and the working mode is normally open.

8.5. Feeding device: the blank from the right furnace passes through the topping device and is rolled off from the transitional slide to the picking roller of the left furnace;

8.6. Temperature sorting device: After the billet arrives at the left furnace roller, the temperature is detected centrally. If the temperature is too high, the front ejector device acts to slide the billet out of the roller to the front return box, if the temperature is low. The rear ejector device moves to slide the blank out of the roller path into the back return box; when the temperature is qualified, the ejector device does not move, and the blank is transported to the forging station.

8.7, infrared thermometer: H -G-2-4-20mA infrared thermometer technical parameters ( Xi'an femtosecond )

Temperature range: 6 00~ 14 00°C (upper limit) Measurement accuracy: ±0.5% (calibration value);

Repeat accuracy : ± 0.1% (nominal value) Response time : 10 ms;

Spectral response : 0.85-1.08 micron output mode : linear output 4 ~ 20 mA

Fiber optic probe : -25°C to 15 0°C Distance factor: 70:1 (energy 90%)

Nine, the external console:

9.1, external console: high and low cabinet style, it is placed at the production site, centralized control of the heating process;

9.2. Operating system: DC, DC current, intermediate frequency voltage, infrared thermometer temperature display, metronome and other display instruments are installed on the console. It is equipped with intermediate frequency start/stop, fault reset button, overcurrent and overvoltage indication. The control unit such as lamp and water temperature alarm can directly control the intermediate frequency power supply and mechanical device on the external console. The core components of the controller are OMRON PLC controllers (control points are configured in two stations) .

X. Complete equipment supply content

Serial number | project name | Specification model | unit | Quantity | Remarks |

1 | IF power cabinet | KGPS- 5 0 0/ 0.5 | station | 2 | Single rectification |

2 | Capacitor bank (furnace bracket) | RW1.2-1000/0.5 s | station | 1 | Double station |

3 | sensor | GTR-1 9 0× 25 00 | station | 2 | |

4 | Ground hoist | station | 1 | With dispensing device | |

5 | Pneumatic pusher | Φ1 3 0× 9 00 | set | 2 | Jinan Huaneng |

6 | Left furnace feed roller | 26 00 (length) | set | 1 | |

7 | Right furnace feed roller | 12 00 (length) | set | 1 | |

8 | Temperature sorting device | set | 1 | Three sorting | |

9 | Right furnace top material device | set | 1 | ||

10 | Infrared Thermometer | HG-2-4-20mA | set | 2 | |

11 | External console | PLC Omron | station | 1 | Shielded cable |

12 | IF cable (or copper platoon) | pay | 2 |

[Note] ZS-1250-10/0.38 rectifier transformers are purchased by the manufacturer and their technical indicators should meet the requirements.

11. The technical information provided by Party B is:

. 11 .1 equipment layout plan, the mounting base, water / gas conduit, power cables, control cables foundation construction FIG.

. 11 .2, KGPS thyristor inverter instructions, equipment maintenance instructions, fault diagnosis and troubleshooting instructions;

. 11 .3, the GTR series of heat through the furnace manual, the load sensor tuning parameters instructions

11 .4 equipment safety procedures

. 11 .5 circuit block diagram of main control board, schematics

11.6 , external console wiring diagram

. 11 .7 mainly purchased parts specification;

. 11 .8, the PLC control scheme, the ladder;

11 .9 equipment inspection certificate factory packing list

The above technical documents concerning technical secrets shall be kept confidential by the manufacturer .

Twelve , random spare parts

name | model | unit | Quantity | name | model | unit | Quantity |

Thyristor core | KP- KK- | One | Each 2 | Integrated circuit block | LM339, LM324 | One | Each 1 0 |

Fast fuse | RSO- | One | Each 5 | Field effect transistor | IRF540N | One | Each 1 0 |

Shi Third, installation and commissioning and acceptance

13.1 Installation: The buyer shall clean the site, lay the water and electricity pipelines according to the supplier's drawings, and place the equipment in accordance with the construction drawings provided by the supplier before the complete equipment arrives. The seller is responsible for the installation and connection of water, electricity and gas pipelines inside the complete equipment.

13.2. Commissioning and acceptance: After the installation of the complete set of equipment is completed, the seller is responsible for the whole machine debugging, according to the relevant provisions of the technical agreement, namely the heating temperature, temperature difference, tact time and other major technical indicators for acceptance; in accordance with the indicators agreed in this technical agreement Then the final acceptance.

Before the equipment is shipped from the factory, the user can send personnel to the supplier's site for pre-acceptance.

Fourteen, after sales service

14.1 Warranty period: The warranty period is one year. The equipment failure during the warranty period starts from the date of receiving the notification (subject to the fax), and the reply is given within 4 hours. Within 48 hours, the maintenance personnel must rush to the scene to freely troubleshoot.

14.2 Technical training: Before the delivery of the equipment or during the commissioning period, the seller is responsible for technical training for the on-site operation and maintenance personnel of the buyer, and the training time is not less than 10 hours. All training is free and provides relevant technical information. The buyer can master the operation essentials and can eliminate common faults.

14.3. Accessories: Provide accessories at preferential prices.

14.4, special warranty: the main control board is guaranteed for three years.

Fifteen , equipment Total: 42 .2 Wanyuan