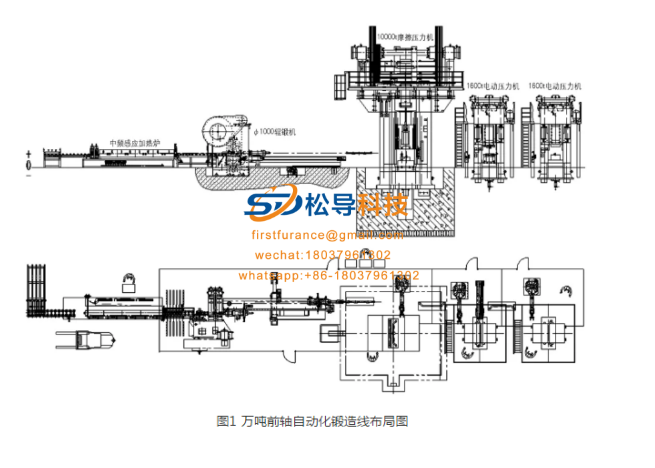

Conventional automobile front axle forging is produced by manual operation, which has high labor intensity and poor working environment. In response to the national intelligent strategy call and the transformation of new and old kinetic energy, build and enhance product competitiveness, and alleviate the bitter, tired and dirty phenomenon of the forging industry. Combining the experience of the first two forging lines, our company started to build a 10,000-ton front axle automatic forging line (Figure 1) in February 2017, which was put into operation in July 2018.

Production line overview

The production line invests more than 17 million yuan, can produce front axle forgings in the range of 40 ~ 160kg, design beats 2.5 ~ 3 minutes / piece, the annual production capacity of 8 ~ 100,000 pieces (two shifts). The pass rate of forgings is 98%, and the utilization rate of forging materials is more than 85%. The process flow of the front axle forging line is: automatic feeding→medium frequency induction heating→3 passes fine rolls→bending, die forging→hot trimming→thermal correction.

Equipment overview

There are 8 complete line configuration equipment, including 1 1250kW medium frequency induction heating device, 1 ZGD1000 automatic roll forging machine, 1 10000t friction press, 2 1600t electric screw presses and 3 KUKA KR360F robots. The successful construction of the 10,000-ton front axle automatic forging line is shown in Figure 2.

(1) 1250kW medium frequency induction heating device.

The 1250kW medium frequency induction heating device is produced by Chongqing Hengrui. The forklift puts the blank on the storage platform, and the pneumatic turning mechanism automatically enters the induction heating in the heating furnace according to the setting command. The temperature measurement system adopts the international advanced German Impac IS310 far infrared thermometer to achieve precise control of material temperature.At the time of discharging, through the three-stage sorting device, according to the temperature value of the material after heating, the round steel with low temperature and high temperature is automatically sorted to achieve precise control of the heating temperature, and the internal heating grains of the material are prevented from being heated too high or too low. Uneven, affecting the internal organization of the product. Guarantee the quality of the front axle, classify and store, and heat the qualified materials through the feeding device to enter the next process.

(2) ZGD1000 automatic roll forging machine.

ZGD1000 automatic roll forging machine is the production equipment of Beijing Electromechanical Research Institute. The maximum blank diameter of roll forging is 160mm. It can be used in conjunction with the robot. The manipulator can move longitudinally and horizontally and feed 180°, and the workpiece is sent to each station for three passes. Roll forging.

The process has the characteristics of forging and rolling. The product has high precision, small surface roughness, good forging quality, saving metal raw materials, high production efficiency, and requires multiple strikes when pulling up on the hammer. The roll forging deformation is continuous static pressure deformation, because the metal fiber structure is continuously distributed according to the outer contour of the forging when the roll is forged, the uniform mechanical properties are good, and the processing after the precision roll forging does not need to be processed, thereby avoiding the disadvantage of the streamline cutting or exposure.

Roll forging continuous rotation, no impact and vibration, less relative sliding between metal and mold, the required equipment tonnage is small, because the roll forging process is a continuous deformation process, each moment of deformation is only in contact with a section, labor conditions are easy To achieve automation, the complex shape roll for such a variable cross section of the front axle is a complex process in which the meshing motion of the rigid body and the plastic flow of the metal in the cavity are intertwined. After the roll is forged, the front shaft is formed into a straight blank, which is ready for the post-press bending and forging.

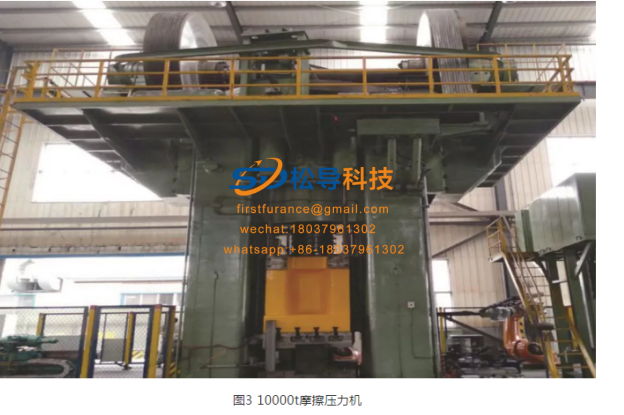

(3) 10000t friction press.

The 10000t friction press (Fig. 3) is produced by Qingdeng Co., Ltd., which performs bending and die forging of straight blank forgings after roll forging. The weight of the equipment is 672t, and the height above the ground is 10.55m. It belongs to a traditional structure of the screw press. The motor drives the two friction wheels to rotate at the same time. When the two friction wheels alternately contact the flywheels on both sides, the flywheel is reversed. Drive the lower end of the screw to move up and down. Achieve a momentary blow to the nominal force of forgings 10000t. After the overall impact force of the forging is increased, the density is increased, the internal structure is firm, the forging is smooth, the forming is full, the corner R arc is the same, the transition is smooth, the forging quality is obviously improved, the forging quality level reaches a new height, and the product competitiveness is improved. .

(4) 1600 ton electric screw press.

Two EPC-type 1600-ton electric screw presses perform flash edge cutting and straightness alignment on the formed forgings. The press has compact structure, short transmission chain, fast striking speed, low energy consumption, high efficiency and convenient operation and maintenance. According to the forging forming process, the pinion on the motor drives the large gear to rotate in the forward and reverse directions to drive the slider up and down. After returning to a certain distance, the motor is powered off, and the energy saved by the flywheel drives the slider up, only in the pressing forging and returning. Work at the time, so the power saving effect is obvious.

(5) KUKA KR360F robot.

Three KUKA KR360F six-axis robots (Fig. 4) are forging robots, which are designed to withstand heat and dust. The blanks held at 1300 °C remain in good working condition. Windows operating system, touch screen panel, 6D space control mouse, different programs for each different product, the program can be produced every time the product is transferred. The three robots are arranged in the bending, die-forging process, hot-cutting process, and heat-correcting process to take the material and feed, instead of manual feeding and turning, the beat operation is stable and reliable.

Conclusion

The whole line of the production line is wrapped with safety fences. When the personnel enters the guardrail area, the equipment in the area stops working to avoid personal injury during production. The signal connection between the various processes starts from the feeding, fully automatic operation, between the equipments. The connection is perfect, reasonable and reliable, and the operation is coordinated and smooth.

Due to special process requirements, the forging industry has graphite milk, high temperature, noise and other pollution, the working environment is very bad, and recruitment is difficult. With the development of science and technology and the improvement of automation level, the application of robots instead of artificial is the development direction of the forging industry. The new forging line situation of our company hopes to provide reference for the improvement of industrial automation.