Features of 50KW high frequency heating furnace : 1. IGBT is used as the main component and full bridge inverter, with perfect protection function and high reliability. 2 , remote control and matching infrared temperature measurement, automatic temperature control, improve heating quality and simplify worker operation. 3 , replace the oxygen smoldering flame, coke oven, salt bath furnace, gas furnace, oil furnace and other heating methods. 4 , using frequency automatic tracking and multi-channel closed-loop control, easy to install, easy to operate.

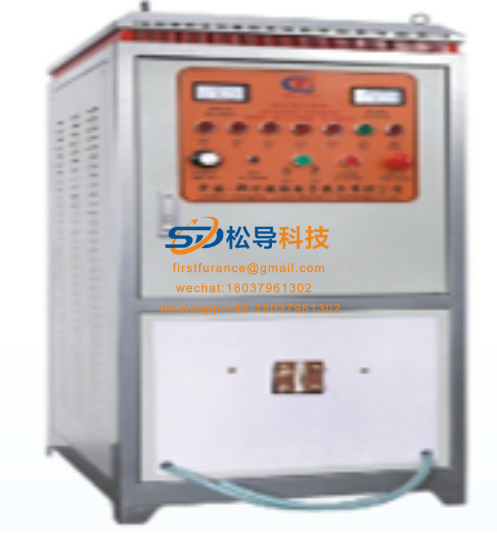

Technical parameters of 50KW high frequency heating furnace:

Working power | Three-phase 380V/50Hz | Cooling water flow (host) | 25L/Min ( 0.1MPa ) |

Operating voltage range | 360V ~ 420V | Cooling water pressure | 0.1 to 0.3 MPa |

Maximum input current | 80A | Water temperature protection point | 55 °C |

Maximum output power | 50KW | weight | 107Kg |

Oscillating frequency | 15 ~ 35KHz | Mainframe dimensions ( mm 3 ) | 550 × 650 × 1260 |

effectiveness | 90% | ||

Load continuation rate | 100% | Special recommendation | Standard parts heating forging industry |

Application range of 50KW high frequency heating furnace: 1. It is applied to heating forging of bar and round steel. 2. This equipment is suitable for heating forging of round steel with diameter less than 25mm . Power saving effect and characteristics of 50kw high frequency heating furnace: 1. Power saving, environmental protection, cost reduction and manpower cost: 30% energy saving than electronic tube and 20% energy saving in thyristor . 2 , product performance is stable, circuit protection is complete, no worries. 3 , ultra-small size , movable, installation, debugging and operation is very convenient, one will be. 4 , induction heating , so that the bar is heated to the required temperature in a very short time, greatly reducing metal oxidation , saving material and improving forging quality. 5 , 24 hours of uninterrupted work. 6. This equipment can realize automatic or semi-automatic feeding. 7 , to facilitate replacement of the sensor , to accommodate different requirements of heating the entire bar end portion or heated.