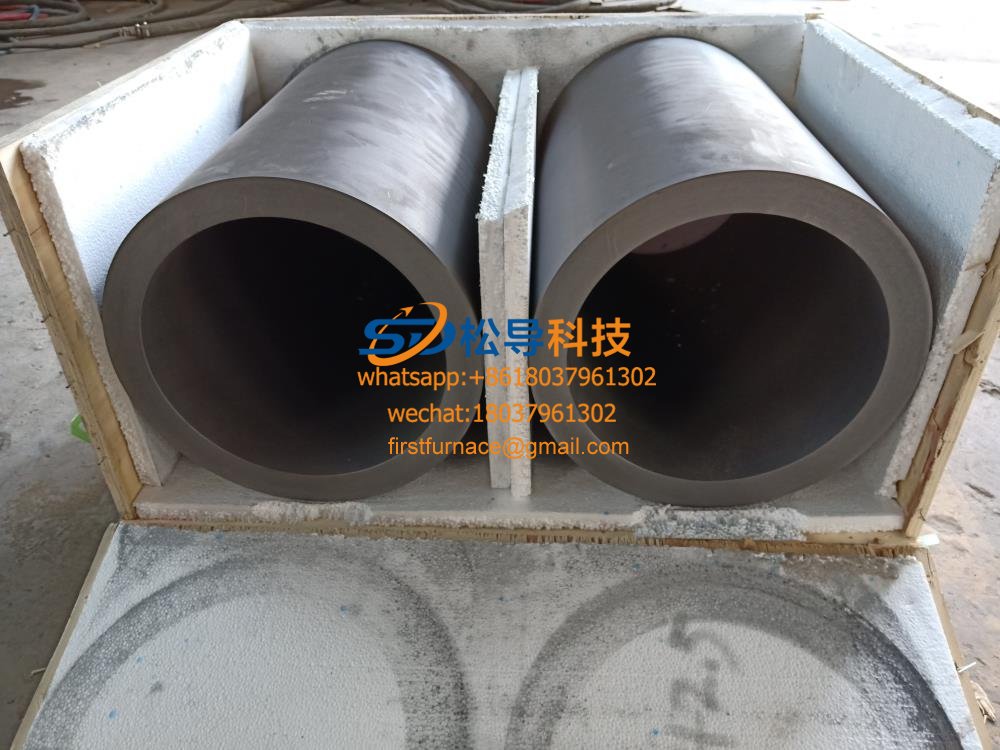

Graphite crucible, general used for melting copper, moelting aluminum, etc., refers to a type of crucible that is fired from graphite, clay, silica and wax. Graphite crucibles are mainly used to smelt non-ferrous metals such as copper, brass, gold, silver, zinc and lead and their alloys.

Advantages

The silicon carbide (Sic) graphite crucible has the following characteristics:

1. Higher thermal conductivity: Shorten the time of smelting, save energy;

2. Higher strength: Shaped by isostatic pressing, internal structure without defects, high physical strength;

3. Better oxidation resistance: Unique antioxidant design, and use high purity raw materials to protect graphite, high oxidation resistance; It’s 5~10 times of ordinary graphite crucible.

4. Anti erosion: low porosity, special additives, effectively resist the corrosion of slag and other melts.

5. long life: Crucible’s life can be 3-5times longer than normal graphite crucible.