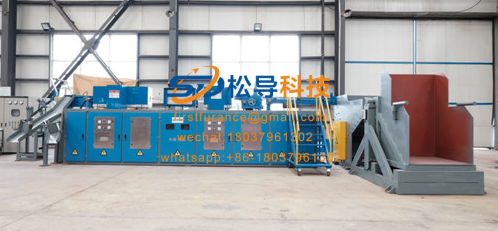

The production line is used for round bar heating and graphite spraying. The main process parameters and technical requirements of the equipment are as follows:

1 , round steel, bar material: 20CrMnTi 20CrMoH SAE4320H 17CrNiMoH .

2 , round steel, bar specifications range: diameter φ32-50mm ; length 70-102mm .

3 , the heating temperature: preheating 100-200 deg.] C , heated 850-950 deg.] C .

4 , beat: φ 42 , length 102mm , 4 seconds / piece.

5 , the heating is stable during normal operation, the temperature fluctuation between each section is within ± 15 °C; after heating, round steel, bar temperature difference: axial (end and tail) ≤ ± 50 °C; radial (core table) ≤ ± 50 °C .

6. The cooling water supply system pressure is greater than 0.5MPa (normal water pressure is greater than 0.4MPa ), and the higher temperature is 60 °C. The corresponding hose pressure and interface also need to be scaled up to safety standards.

Graphite spraying can protect round steel and bar material in the cold state of round steel and bar, anti-oxidation and anti-decarburization. In the extrusion process, graphite also plays the role of lubricating and protecting the mold.