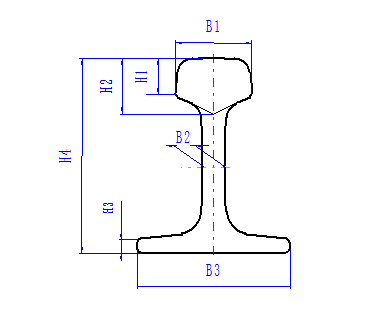

End of the rail portion intermediate quenching apparatus capable standard rail end 37-75kg / m rail portion hardening, while adapting production UIC54-60 rail and tram tracks. (See the figure below for each section).

Rail model | B1 | B2 | B3 | H1 | H2 | H3 | H4 |

38Kg | 68 | 13 | 114 | 27.7 | 39 | 9 | 134 |

43Kg | 70 | 14.5 | 114 | 30.4 | 42 | 11 | 140 |

50Kg | 70 | 15.5 | 132 | 33.3 | 42 | 10.5 | 152 |

60Kg | 75 | 16.5 | 150 | 36.33 | 48.5 | 12 | 176 |

75Kg | 75 | 20 | 150 | 46 | 55.3 | 13.5 | 192 |

UIC54 | 72.2 | 16 | 140 | 36.3 | 49.4 | 11 | 159 |

UIC60 | 74.3 | 16.5 | 150 | 37.5 | 51 | 11.5 | 172 |

D60 | 116 | 12 | 160 | 30 | 38.6 | 8.5 | 161.3 |

Quenching process requirements ( rail end portions technical standards quenching performed)

After the rail end intermediate frequency quenching equipment applies electric induction heating and quenching to the end of the rail , it should meet the technical requirements of GB2585--standard and Japanese JIE1123-1989 standard.

The steel grade of the rail and the tensile strength of the rolled state are shown in the following table.

Brand | chemical composition | tensile strength Бb .MPa | ||||

C | Si | Mn | P | S | ||

U74 | 0.67~0.80 | 0.13~0.28 | 0.70~1.00 | ≤0.035 | ≤0.035 | ≥780 |

U71Mn | 0.65~0.77 | 0.15~0.35 | 1.10~1.50 | ≤0.035 | ≤0.035 | ≥880 |

U70Mn | 0.60~0.80 | 0.10~0.50 | 0.85~1.25 | ≤0.035 | ≤0.035 | ≥880 |

UIC-900B | 0.55~0.75 | 0.10~0.50 | 1.30~1.70 | ≤0.040 | ≤0.040 | ≥1030 |

EN-260Mn | 0.53~0.77 | 0.15~0.60 | 1.25~1.75 | ≤0.030 | ≤0.030 | ≥880 |

* U70Mn is the same as 900A in UIC860.

The rail end quenching equipment can perform rail end quenching on 38-75kg/m rail, and can also adapt to the production of UIC54 ~ 60 rail and tram rail. The medium frequency heating and quenching process of the complete equipment are controlled by the PLC program, which can fully meet the technical requirements of the GB2585 standard and the Japanese JIE1123-1989 standard.

Rail end intermediate frequency quenching equipment

1, 160kw/2.5KHz intermediate frequency power supply (air cooling) 6 sets ,

2, capacitor cabinet 6 sets

3, 6 sets of control cabinets (Siemens S7-CPU315 series, dual master station, dual CPU, one CPU master station controls 1, 2, 3, 4 quenching machine, another CPU master station controls 5, 6 quenching machine)

4, programming dedicated portable computer 1

5, quenching machine (3.5t / set, including quenching device, clamping device) 6 sets

6, quenching device 6 sets (hot water generator, quenching special nozzle)

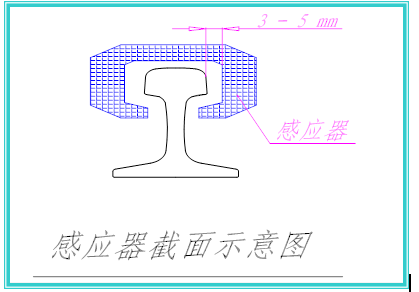

7, PR-500KVa quenching transformer 6 sets of sensors (60 rails)

8, clamping and positioning device (12 pieces) 6 sets

9, hydraulic station 6 sets

10, hydraulic and cooling water pipeline system 6 sets

11, spray water, air lines and pipe fittings (water, gas filter, electromagnetic opening and closing valve, pressure reducing valve, flow meter, etc.) 6 sets

12, temperature measurement system (US Leitai-G5SF400-1200 °C) 6 sets

Related reference:

1,Overall structural design of rail end quenching machine,

2,Brief description of heat treatment process of rail end