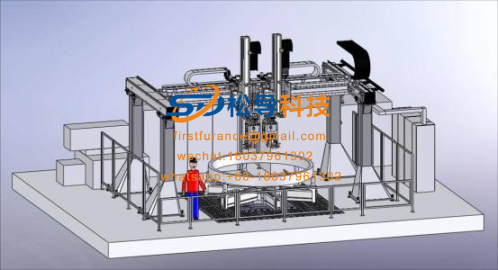

Heat treatment process of flywheel ring gear high frequency quenching equipment

Use Flywheel ring gear high frequency quenching equipment for quenching heat treatment during a very important process, after quenching heat treatment of metal having higher hardness and wear resistance than before, so that the actual service life. Flywheel ring gear is no exception. According to many users, quenching the ring gear with an all-solid induction heating furnace can greatly improve its hardness and other comprehensive mechanical properties. Today, lead everyone to learn about the related quenching process!

Under normal circumstances, the flywheel ring gear adopts heating and rotary quenching once; spraying liquid once after heating, and controlling the spraying time to obtain self-tempering. The quenching cooling medium is generally 15-30 ℃ water. There are two ways to spray liquid. The first method is to drill a spray hole in the induction coil of the all solid-state induction heating furnace . After heating to the required temperature and pre-cooling, spray water directly for a few seconds, and then stop spraying to make the ring gear center. The internal heat is transferred to the outer surface, causing the gear teeth to self-temper. The self-tempering temperature is 300 -400 ℃ according to the hardness requirement . Flywheel ring gear quenching equipment using the most major benefits in addition to energy saving, since the solid-stateinduction heating furnace . an internal circuit adopt IGBT power module and a unique inverter technology, high efficiency, timely cooling, can be very effectively avoid quenching the teeth portion The occurrence of cracking, oxidation, and decarburization. Note that, when using this method of quenching the ring gear, the liquid discharge aperture of the sensor with the growth of production time, easy to gradually decrease (the hardness of the water, i.e., containing CaC03 related ) . Therefore, after a period of production according to the prescribed process, it is often found that the temperature after quenching has increased. The reason is that the cross-section of the spray hole is reduced, resulting in a reduction in the spray volume. For this reason, this sensor must be periodically mass fraction of 10% of HCl was pickled to remove scale on the liquid discharge hole. The second method is to heat the ring gear with a toroidal inductor. After heating and pre-cooling, the ring gear falls into the sprayer for quenching and subsequent cooling. After this method is heated, the workpiece must fall into the sprayer correctly. This kind of sensor has a longer service life than the first one, butOne more descending action.