Intermediate frequency heating furnace for heating automobile stabilizer bar

At present, in the production of automobile stabilizer bars, a high-temperature oil burner is used to heat the stabilizer bar. The stabilizer bar is placed in the furnace for centralized heating, and it needs to go through the process of preheating, heating and heat preservation. The heating time is long and the speed is slow. Due to the large volume of the oil burner, A lot of energy is wasted every time it burns, which also increases the production cost of the stabilizer bar.

Now provide an intermediate frequency heating furnace that can heat a single stabilizer bar, with short heating time, high speed, and energy saving.

It includes a bracket. The bracket is equipped with several intermediate frequency heating furnace bodies. The side of the intermediate frequency heating furnace body has a workpiece inlet. The intermediate frequency furnace body has a furnace ring made of hollow copper pipes. The bracket is equipped with a water inlet and a drain main pipe. There are several water inlet pipes and drain pipes on the circle. Both the water inlet pipe and the drain pipe extend from the intermediate frequency furnace body. The water inlet pipe is connected with the water main pipe, and the drain pipe is connected with the drain main pipe. There is an air cylinder, the end of the cylinder rod of the cylinder is fixed with a connecting plate, a support plate is fixed on the bracket, a guide roller is installed on the support plate, and a far-infrared detector is also installed on the bracket. The advantage is that the workpiece stabilizer bar is hooked on the connecting plate during use, and the workpiece stabilizer bar is placed on the guide roller. The cylinder works, and the connecting plate sends the workpiece stabilizer bar into the intermediate frequency heating furnace for heating. After heating, the cylinder 1 This device can heat a single stabilizer bar, with short heating time, fast speed, simple structure, energy saving, and lower production cost of the stabilizer bar.

Description of the drawings

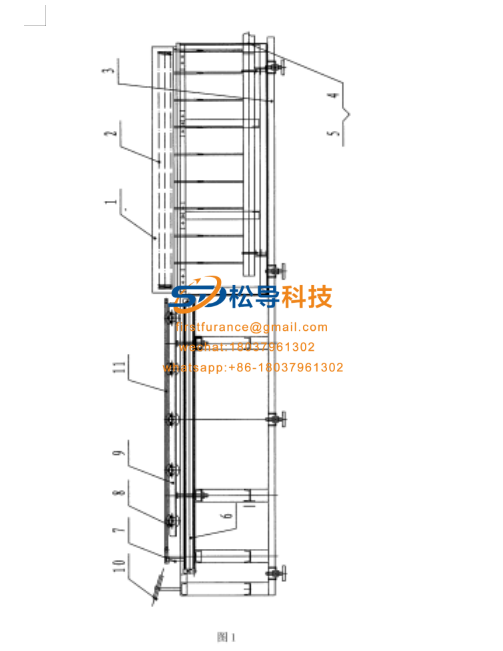

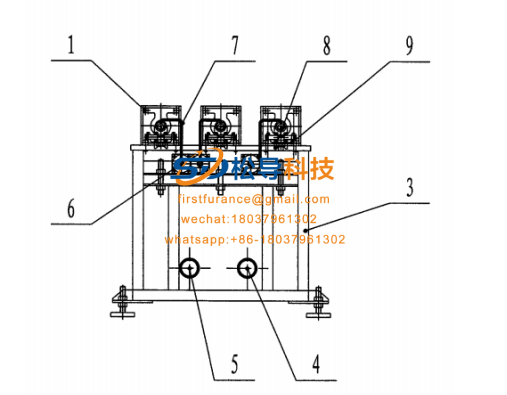

Figure 1 is a schematic diagram of the structure of the utility model, and Figure 2 is a workpiece stabilizer bar

Figure 2 is a side view of the utility model.

Intermediate frequency heating furnace for heating automobile stabilizer bars. It includes a bracket 3, on which a number of intermediate frequency furnace bodies 1 are installed, the side of the intermediate frequency furnace body is provided with a workpiece inlet, and the intermediate frequency furnace body has a furnace ring 2 made of hollow copper pipes. The bracket is equipped with a water inlet main pipe 5 and a drain main pipe 4 There are several water inlet pipes and drain pipes on the furnace ring. Both the water inlet pipe and the drain pipe extend from the intermediate frequency furnace body 1. The water inlet pipe and the water inlet main pipe 5 are connected, and the drain pipe and the drain main pipe 4 are connected, and the intermediate frequency furnace body works The bracket in front of the entrance is equipped with an air cylinder 6, the end of the cylinder rod of the cylinder is fixed with a connecting plate 7, a supporting plate 9 is fixed on the supporting plate, a guide roller 8 is installed on the supporting plate, and a far-infrared detector 10 is also installed on the supporting frame.http://www.songdaokeji.com/plus/list.php?tid=42

http://www.songdaokeji.com

http://www.songdaokeji.com/plus/list.php?tid=52