The vacuum induction melting furnace is mainly used as a melting furnace for smelting gray cast iron, malleable cast iron, nodular cast iron and alloy cast iron. When the vacuum induction melting furnace is working, the furnace environment is harsh, and the temperature in the furnace quickly rises to more than 1700 ℃ in a short time . And after the metal is melted, it has a self-mixing process under the action of electromagnetic field during the smelting process, which is very erosive and erosive to the working layer. The industry of vacuum induction melting furnaces for metal smelting is often dominated by alkaline refractory materials, which have high thermal conductivity and are easy to conduct heat to the insulating layer, which affects the use of induction coils, and the loss of heat will also cause the furnace The decrease in the temperature of the internal metal liquid affects the smelting effect; and the furnace body temperature is high, and the working environment of the staff is poor, which brings hidden dangers to the health of the staff.

According to the above deficiencies in the prior art, the technical problem to be solved by the utility model is to provide a

Vacuum induction melting furnace for metal smelting with less heat loss and lower furnace temperature .

Vacuum induction melting furnace for metal smelting , including furnace body, furnace cover, bottom leaky tube, vacuum channel, multiple sets of induction coils and crucible, in which the furnace body and furnace cover are double-layer structure, the inner layer is heat insulation layer, the outer layer The layer is a water-cooled layer; the vacuum channel is connected to a vacuum pump.

The furnace body and the furnace cover are provided with heat insulation layers, which can effectively reduce heat loss and prevent the temperature of the metal liquid from decreasing, and

And reduce the heat transferred to the furnace body, lower the temperature of the furnace body; with a water cooling layer, which can further reduce the temperature of the furnace body;

Connected to a vacuum pump, it can put the metal to be smelted under vacuum to reduce its melting point, and can play a role in protecting the equipment

use.

A support frame is provided between the inner wall of the bottom of the furnace body and the outer wall of the crucible, and a heat insulation sleeve is provided on the outer circumference of the crucible. The heat insulation sleeve naturally rests on the support frame, and multiple sets of induction coils are wound on the outer circumference of the heat insulation sleeve. The provision of a support frame serves to fix the crucible on the one hand, and to prevent the heat-insulating jacket from sliding down on the other hand, so that the upper coil directly contacts the outer wall of the crucible and burns the coil.

Both the furnace body and the furnace cover are provided with a water inlet and a water outlet, and cold circulating water can effectively reduce the temperature of the furnace body and the furnace cover.

The bottom leakage pipe is provided with an electric control valve, which is convenient for controlling the removal of processed materials.

The vacuum induction melting furnace for metal smelting is provided with a heat insulation layer on the furnace body and the furnace cover, which can effectively reduce the heat loss, prevent the temperature of the metal liquid from lowering, and reduce the heat transferred to the furnace body and reduce the temperature of the furnace body; There is a water cooling layer, which can further reduce the temperature of the furnace body and improve the working environment of the staff.

BRIEF DESCRIPTION

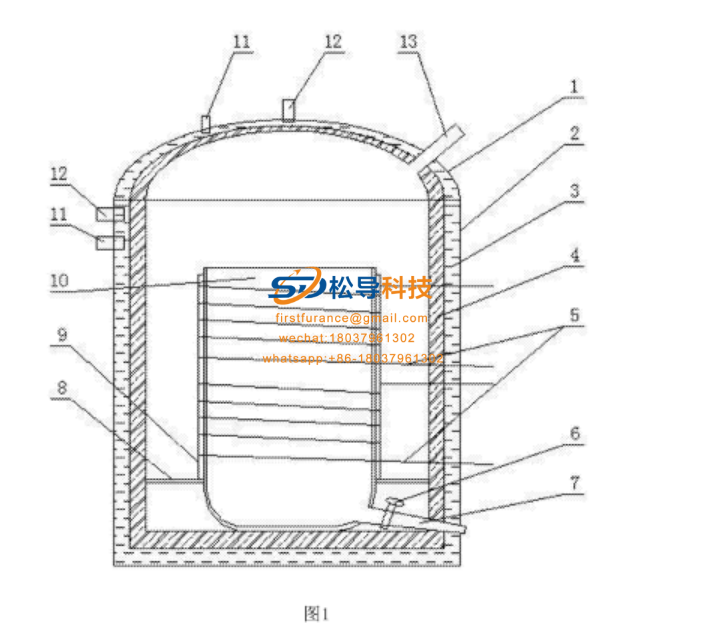

Figure 1 is a schematic diagram of the utility model.

In the picture: 1. Furnace cover ; 2. Furnace body; 3. Water cooling layer; 4. Heat insulation layer; 5. Coil; 6. Electric control valve; 7. Bottom leakage pipe; 8. Support frame; 9. Heat insulation sleeve ; 10 , crucible; II , water inlet: 12 , water outlet; 13 , vacuum channel.

The following further describes the embodiments of the present invention with reference to the drawings:

As shown in FIG. 1 , the vacuum induction melting furnace for metal smelting according to the present invention includes a furnace body 2 , a furnace cover 1 , and a bottom

Leakage tube 7 , vacuum channel 13 , multiple sets of induction coils 5 and crucible 10 , of which the furnace body 2 and furnace cover l are both double-layer structures, the inner layer is heat insulation layer 4 and the outer layer is water cooling layer 3 ; vacuum channel 13 Connect the vacuum device. The heat insulation layer 4 is provided on the furnace body 2 and the furnace cover l , which can effectively reduce the heat loss, prevent the temperature of the metal liquid from lowering, and reduce the heat transferred to the furnace body 2 and reduce the temperature of the furnace body 2 ; a water cooling layer is provided 3. The temperature of the furnace body 2 can be further reduced ; a vacuum extraction device can be connected to place the metal to be smelted under vacuum to reduce its melting point and protect the equipment.

Furnace 2 at the bottom of the crucible and the inner wall 10 is provided between the outer wall of the support frame 8 , crucible 10 the outer periphery of a heat insulating sleeve 9 , the insulation jacket 9 natural resting support frame 8 , the insulating sleeve 8 an outer periphery of the wound There are multiple sets of induction coils 5 and a support frame 8 is provided . On the one hand, it functions to fix the crucible 10 , on the other hand, it can prevent the insulation jacket 9 from sliding down, and make the upper coil 5 directly contact with the outer wall of the crucible 10 to burn the coil; The support frame 8 is a high temperature resistant insulating material; the furnace body 2 and the furnace cover 1 are provided with a water inlet II and a water outlet 12 , cold circulating water can effectively reduce the temperature of the furnace body 2 and the furnace cover 1 ; the bottom leakage pipe 7 is provided with The electric control valve 6 is convenient for controlling the removal of processed materials.

[0018] The present invention said metal melting vacuum induction melting furnace , the furnace body 2 and the lid l are disposed on the insulating layer 4 ,

Can effectively reduce the heat loss, prevent the temperature of the metal liquid from decreasing, and reduce the heat transferred to the furnace body 2

The furnace body 2 temperature; water-cooled layer 3 can be further reduced furnace 2 temperature, improve the working environment of staff.