Irregular workpiece in the electric field lines in FIG. " Profiling " design, parts cusp effect, the thin walls of the hole " short circuit " phenomena are concerns in the design. Therefore, at this time, it is mainly to analyze the problems that are easily overlooked in the " profile " design of the intermediate frequency quenching inductor .

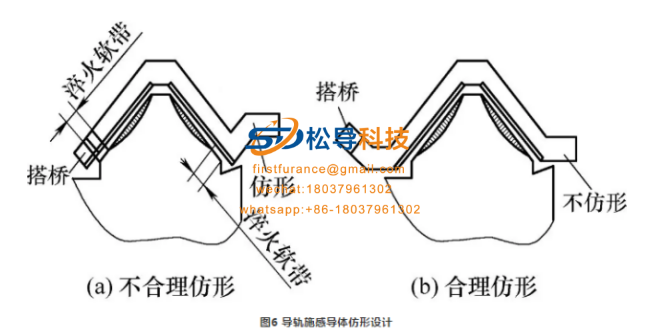

( 1 ) IF quenching electrical sensing conductor between the preheating and the heating coil has a coil end quenching " bypass " , which bypass short (typically effective length of 15mm ), the preheating current direction, perpendicular to the heating coil current, magnetic field The strength is weak and the heating efficiency is low. The 10cm and 16cm soft band areas are prone to appear at the bridges of 10mm × 8mm and 6mm × 10mm rectangular tubes . Therefore, “ bridging ” cannot be regarded as an effective heating area for “ profile ” . As shown in Figure 6a , the " bridging " makes a soft tape at the root of the mountain guide rail, which should be changed to the heating method shown in Figure 6b . In addition, it should be pointed out that in Fig. 6a , the profiling and easy operation of the oil groove are considered blindly, the problem of poor heating efficiency of the groove and difficulty in placing the magnetizer are ignored, and the hardened soft belt is also caused. 6b way improvement.

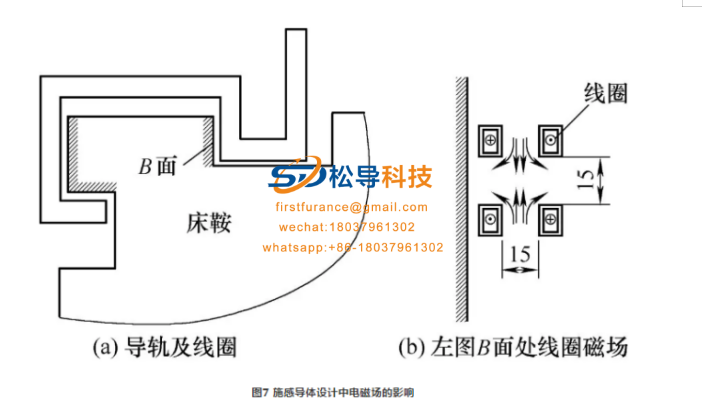

( 2 ) The influence of electromagnetic field of " profile " line graph. FIG 7 is a saddle rail IF quenching electrical sensing conductor, since the surface hardening scattered separately, in order to improve electrical work efficiency, according to the original design " profiling " manufactured FIG. 7a type diagram, it seems from the design size, surface hardening selected viewed It's reasonable, but in reality, there is a phenomenon that the B side can't be quenched with " fire " .

Analysis: From B surface electrical sensing conductor cross-section (see FIG. 7b instantaneous magnetic field that), the 15mm × 15mm region, 4 electromagnetic coil weakening the root of each other, consumed, so that B surface flux density decreases, additional B surface other The quenched surface has better heat dissipation than heat dissipation, which ultimately leads to the failure to heat to the quenching temperature, even if the magnet is used, the nature of the weak electric field induction cannot be changed. For this, the design can only be improved, and the B surface is quenched separately with a flat type inductor.

Layout method of guide magnet of machine tool guide rail quenching equipment

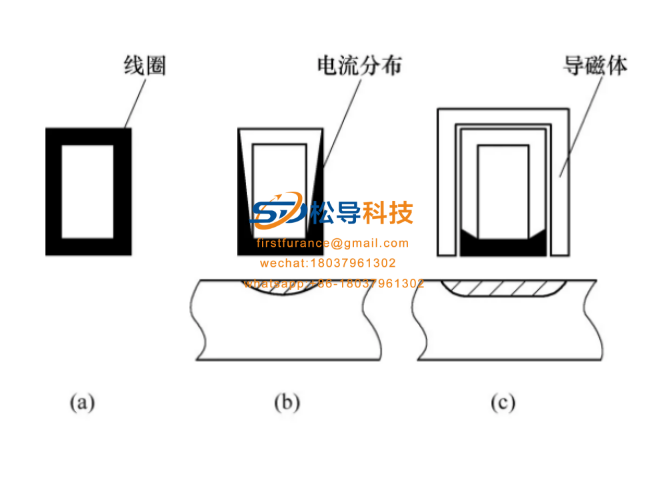

As an important part of the inductor, various sizes and forms of magnetizers have been widely used in induction heat treatment because magnetizers can improve the magnetic coupling efficiency and can significantly improve the quality of induction heating in local areas. The role of the magnetizer in the inductor is shown in Figure 8 .

FIG 8a shows a current distribution in the coil, the workpiece placed, because the proximity effect, power the induction coil current flow through a large part of the surface of the workpiece adjacent the side of the distribution in FIG. 8b shown; FIG. 8c is placed П type After the magnetic conductor, the current distribution diagram of R in the coil , it is obvious that the current is " concentrated " at the slot surface at this time , thereby improving the magnetic coupling efficiency. Therefore, it is necessary to consider whether to use the magnetizer and the determination of the magnetizer position in the design. In the design and selection of the inductor, the actual workpiece processing size should also be determined, because the workpiece generally has a pre-grinding processing amount after heat treatment, so the process route should be analyzed and the cold and hot process countersign system should be implemented. In the design, attention should also be paid to the dynamic strength of the sensor, especially the medium frequency quenching heating sensor. Due to the large electromagnetic attraction between the workpiece and the coil during heating, the sensor with poor mechanical strength is likely to cause the sensor to vibrate, and even appear to be in contact with the workpiece. A short-circuit phenomenon occurs upon contact.

Machine tool guide rail quenching equipment : http://www.songdaokeji.com/plus/view.php?aid=208