Induction melting furnace furnace comprising a furnace shell, the bottom of the furnace shell and furnace floor is provided with a furnace bottom refractory brick furnace furnace opening, the housing has an upper furnace port and the furnace shell and the refractory bricks fixedly connected to one panel of the furnace, the furnace panels and the furnace The shells are made of aluminum alloy, while the furnace floor and furnace mouth are cement asbestos boards. Aluminum alloy has poor mechanical properties and poor impact resistance at high temperature ( melting point 700 ℃) , which makes the furnace body of induction melting furnace high in cost and short in service life. Cement asbestos wrenches are not impact resistant, have particularly poor seismic performance, are easily cracked, fragile, and have a short service life. Generally , they must be replaced in about 2 months. Further furnace bottom refractory brick and refractory furnace port drawbacks include high cost.

Transformation object is to overcome the above disadvantages and to provide an improved induction furnace melting furnace body.

Transformation is provided an induction melting furnace body, comprising a snout, the furnace shell, with a bottom portion of the furnace shell and the furnace bottom refractory base layer, an upper furnace port plate has a furnace shell, the furnace opening fire-resistant layer, is fixedly connected with the furnace shell The integral furnace panel and the short and long screws and nuts connecting the furnace shell and furnace body are characterized in that the furnace panel and the furnace mouth plate are made of alloy steel. Due to alloy steel

It has excellent mechanical properties, high temperature resistance and melting point of 1400 ℃ , so the service life of the furnace panel of the induction melting furnace body is prolonged and the cost is reduced. Can be used for 3 to 5 years. The impact resistance and seismic performance of the furnace mouth plate are improved, not easy to break, not easy to crack, the service life is greatly extended, and the cost is greatly reduced.

The above furnace shell and furnace bottom plate are made of alloy steel, and the furnace mouth refractory layer and furnace bottom refractory layer are prefabricated drawings of reinforced cement. The furnace shell and the bottom plate of the furnace are made of alloy steel, so that the service life of the furnace shell of the induction melting furnace body is extended, the cost is reduced, and it can be used for 3 to 5 years. It improves the impact resistance and seismic resistance of the furnace floor, is not easy to break and crack, and the service life is greatly extended.

The cost is greatly reduced. The cost of reinforced cement prefabricated ring is lower, use it to replace the refractory brick

And the bottom refractory brick can reduce the cost of induction melting furnace body.

The above alloy steel is an alloy steel with a manganese content greater than 8% and a chromium content less than 12% . The short and long screws and nuts connecting the furnace shell and the furnace body are made of stainless steel. The short and long screws and nuts originally connected to the furnace shell and furnace body are made of brass, and the cost of brass is higher than that of stainless steel.

After the above furnace mouth is formed by welding with stainless steel, it is made of furnace sand.

The transformation has the following characteristics:

The furnace panel and furnace shell have a long service life, low cost, good impact resistance and earthquake resistance of the furnace floor and furnace mouth plate, are not fragile, and are not easy to crack, long service life, low cost, reinforced cement prefabricated drawings and short and long stainless steel Screws and nuts have the characteristics of low cost. Therefore , the manufacturing cost of the transformation is greatly reduced.

The following describes the implementation side of the transformation with reference to the drawings :

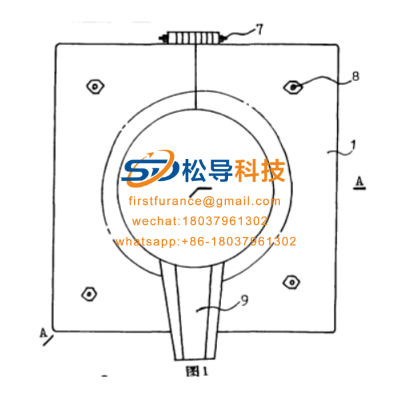

Figure 1 is a schematic view of the top structure of the transformation

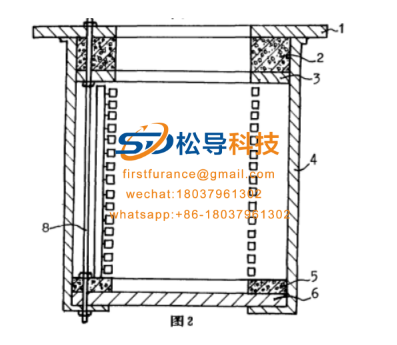

FIG. 2 is a cross- sectional view of FIG. 1 along AA section

Refer to Figure 1 ~ Figure 2 : The transformation includes furnace mouth 9 and furnace shell 4, furnace mouth 9 is made of stainless steel welding, and then built with furnace sand. Furnace shell 4 is made of steel, the furnace shell 4 has the oven floor 6 and hearth refractory layer, pull hearth 6 is made of steel, the refractory bottom layer is a precast reinforced concrete ring 5 in the furnace shell 4 upper portion furnace mouth plate 3, oven opening and connected to the refractory layer as one of the furnace shell welded furnace panel, the furnace mouth plate 3 and the furnace panels 1 are made of steel, the furnace opening is reinforced concrete precast refractory layer collar 20 of the Alloy steel has a manganese content greater than 8% . Alloy steel with chromium content less than 12% . Furnace shell 4 above the inner member by the length of the screw 8 and a nut secured in the furnace shell 4 within the furnace shell 4 by a short screw 7 and the nut is secured integrally. The long and short screws 8 , 7 and nuts are made of stainless steel.