KGPS-1T-3 induction melting furnace can save 80-100 degrees per ton of steel (consumption power can be as low as 520 degrees / ton of molten steel) compared with other types of 1T electric furnace.

First, the electric cabinet:

1, rated phase voltage: 700V, intermediate frequency output voltage 1300V, DC current: (maximum) 1000A, power (maximum): 1000KW

2, KK thyristor 1000A/2000V 8

3, KP thyristor 1000A/2500V 6

4, air switch 2000A

5, installed copper row 80 mm X 6 mm

6, reactor (copper tube diameter 15mm, wall thickness 1.5mm coil, 12), a balanced reactor

6, intelligent system

Second, the capacitor cabinet:

Capacitor 2000KF / 1200V 6 sets, 360KF/1200V 1 set

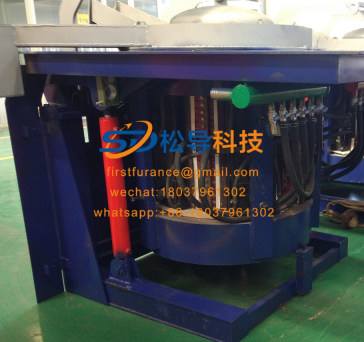

Induction melting furnace

Reducer: 531

Furnace shell: diameter 1230 mm high 1390 mm.

Induction ring: Copper tube 25 mm X 30 mm X 3 mm Inner diameter 660 mm 25 turns.

Features:

1. Intelligent system, fast protection, durable thyristor, good starting performance, stable operation and convenient operation.

2, using a large copper rowing machine, saving electricity.

3, using 2 tons of electric furnace structure, the furnace bottom heat is small, the furnace bottom is durable, not easy to wear the furnace, the furnace bottom loss is small; using the booster circuit, the voltage at both ends of the electric furnace can reach 2600V (two times the output voltage of the electric cabinet), Water cable and induction coil loss are small; 700V phase-in phase voltage, reactor, installed copper row, and phase-in phase cable loss are small.

http://www.songdaokeji.com/plus/list.php?tid=22