Induction melting furnace with household excessive pursuit of high voltage (some 1000KW using 900V line voltage), since low current to save energy, so do based on the life of electric furnace for the price, not worth the candle, likely to cause high voltage frequency power supply of The life of the components is shortened, the copper bars and cables are damaged , and the life of the induction melting furnace is greatly reduced. In addition, the high voltage for the induction melting furnace manufacturers , the use of materials to reduce raw materials, saving costs. Induction melting furnace manufacturing factory is willing to do so (the high price of low cost), but ultimately lose out or casting enterprises .

When selecting the induction melting furnace, the foundry company should select the following according to the transformer capacity, production requirements, investment quota, etc., when purchasing the induction melting furnace:

A. Transformer capacity For the industry's commonly used SCR full-bridge parallel inverter frequency power supply , the numerical relationship between transformer capacity and power supply is: transformer capacity (KVA) = power supply (KW) x 1.25 ( Note: 1.25 is the safety factor) . The transformer is a rectifier transformer. In order to reduce the interference of harmonics, it is used as far as possible for the special plane, that is, one intermediate frequency power supply is equipped with a rectifier transformer.

B , incoming line voltage for medium-frequency power supply below 1000KW generally adopts three-phase five-wire 380V , 50HZ industrial power, with 6- pulse single-rectified intermediate frequency power supply; for medium-frequency power supply above 1000KW , it focuses on using 660V incoming voltage (not recommended) Choose a non-standard voltage level of 575V or750V , )

Configuration 12 pulse frequency power supply , which is the main reason there are two explanations :

1 , is to increase the rated working voltage of the induction melting furnace by increasing the incoming line voltage;

2 , the harmonic generated by high power will interfere with the grid. The double rectification can obtain a relatively straight DC current. The load current is a rectangular wave, and the load voltage is close to a sine wave, which reduces the impact of grid interference on other equipment.

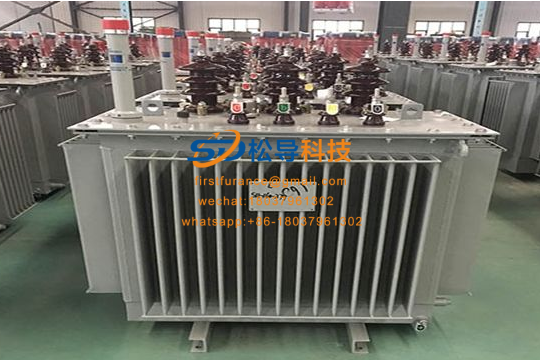

Induction melting furnace dedicated transformer

Induction melting furnace dedicated transformer selection reference :

1 , Method for selecting 1T intermediate frequency

2 , How to choose the transformer of the induction melting furnace?

3 , Transformer selection for medium frequency furnace power supply

4 , Technical description of special rectifier transformer for induction melting furnace