Equipment name: sucker rod heat treatment line

workpiece material: carbon steel alloy steel

workpiece size: diameter 20 mm or more

power range: 160- 1000KW

closed-loop temperature control: US Leitai two-color thermometer control temperature

control system: PLC people Machine interface automatic intelligent control

Description of the process flow and working process of the sucker rod heat treatment line :

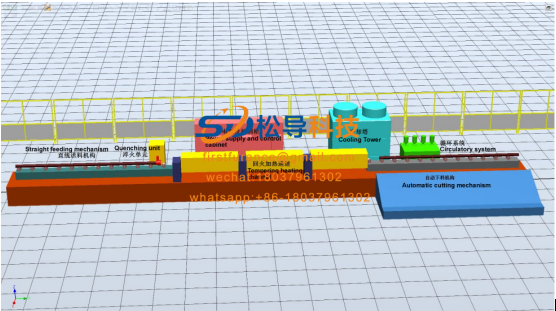

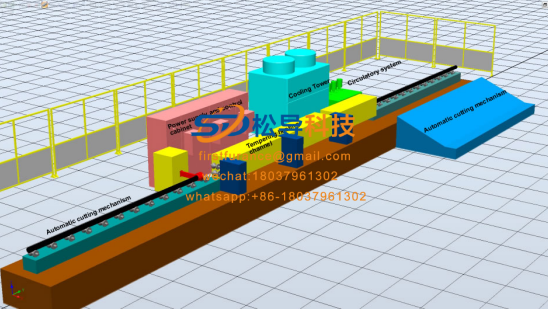

1. Heat treatment process: The steel pipe is placed on the loading platform by the crane to carry out the baling → feeding machine feeding → variable frequency feeding roller to transport the steel pipe forward → quenching medium frequency induction heating sensor (low temperature) furnace, (high temperature) furnace Heated to 950 °C infrared temperature measurement and feedback to form a closed-loop control to adjust the power of the intermediate frequency induction heating furnace → spray quenching → lift the pipe through the turning machine and put it on the residual water draining device in the pipe → lift the pipe through the turning machine On the tempering roller road → (low temperature) tempering induction heating furnace → (high temperature) tempering medium frequency induction heating sensor (heating) heating to 450 ~ 760 ° C infrared temperature measurement and feedback composition of closed-loop control adjustment medium frequency induction heating furnace power → turn Feeder→chain two-way cold bed→turning machine→ discharge . ![]()

![]()

2. Summary of technical parameters of sucker rod heat treatment line

size | Control System | Supporting power supply |

Φ 10- Φ 28mm | PLC intelligent control | KGPS350KW + KGPS160KW |

Φ 42- Φ 48mm | PLC intelligent control | KGPS250KW + KGPS160KW |

Φ 30- Φ 60mm | PLC intelligent control | KGPS250KW + KGPS160KW |

Φ 30- Φ 60mm | PLC intelligent control | KGPS250KW + KGPS160KW |

Φ 35- Φ 60mm | PLC intelligent control | KGPS300KW + KGPS160KW |

Φ 30- Φ 110mm | PLC intelligent control | KGPS400KW + KGPS160KW |

Φ 80- Φ 110mm | PLC intelligent control | KGPS600KW + KGPS160KW |

Φ 73.2- Φ88.9mm- Φ139.7 mm | PLC intelligent control | KGPS500KW + KGPS100KW |

Φ 95- Φ 114mm | PLC intelligent control | KGPS250KW + KGPS160KW |

Customized production according to the actual needs of customers | ||

Related Information:

2,Sucker rod heat treatment line production line configuration composition and characteristics:

3,What is the composition of the sucker rod heat treatment line?

4,Performance characteristics of the sucker rod heat treatment line: