product description:

Medium frequency aluminum melting furnace equipment features:

1 , the main application:

The intermediate frequency aluminum melting furnace uses aluminum , scrap aluminum, aluminum ingots, and aluminum alloy for melting heating; the melting amount ranges from 100 KG to 300 00 KG . ,

2 , the basic composition of the intermediate frequency aluminum melting furnace :

Including medium frequency power supply, compensation capacitor box and melting furnace. According to different application requirements, it may also include infrared thermometers, temperature controllers and other devices;

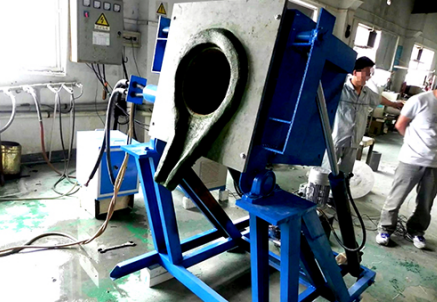

There are three types of aluminum melting furnaces: a turn-over melting furnace, a top-out melting furnace and a stationary melting furnace. The tip-up melting furnace can be divided into a mechanical tipping furnace, an electric tipping furnace and a hydraulic tipping furnace according to the overturning manner.

Characteristics of medium frequency aluminum melting furnace :

a, medium frequency melting has a good electromagnetic stirring effect, which is beneficial to the melting metal temperature and the uniformity of the structure, which is beneficial to scumming and reducing impurities;

b, Wide frequency range, from 1KHZ to 20KHZ , can consider the melting amount, electromagnetic stirring, heating efficiency, noise during operation and other factors to design the induction coil and matching compensation capacitor to determine the output frequency;

c, using thyristor intermediate frequency power supply , energy saving at least 20% ;

3 , Medium frequency aluminum melting furnace specification selection table :

Product number | power | capacity | Melting speed |

SDRL-100 | 30KW | 100KG | 40KG/H |

SDRL-200 | 40KW | 200KG | 100KG/H |

SDRL-300 | 60KW | 300KG | 180KG/H |

SDRL-400 | 80KW | 400KG | 240KG/H |

SDRL-500 | 100KW | 500KG | 300KG/H |

SDRL-600 | 120KW | 600KG | 350KG/H |

SDRL-800 | 150KW | 800KG | 420KG/H |